To clean points on a distributor, disconnect the distributor cap, remove the points cover, and scrub the points with a fine-grit sandpaper or a point file to remove any corrosion or dirt buildup. Then, reconnect the points cover and distributor cap.

Understanding The Distributor Points

Regular maintenance of your vehicle’s ignition system is essential for optimal engine performance. One crucial component of the ignition system is the distributor and its points. Distributor points play a vital role in delivering spark to the engine’s cylinders at the right time, ensuring efficient combustion.

In this section, we will dive deeper into what distributor points are, how they function in an ignition system, and the impact of dirty and worn-out points on engine performance.

What Are Distributor Points?

Distributor points, also known as breaker points, are mechanical contacts located inside the distributor. They function as a switch that controls the flow of current in the ignition system. The points open and close to create a spark, which is then distributed to the appropriate spark plugs to ignite the air-fuel mixture in the combustion chambers. These points are typically made of tungsten or a tungsten alloy for durability and longevity.

How Do Distributor Points Function In An Ignition System?

Within the distributor, the points are connected to the ignition coil and the distributor cam. As the distributor shaft rotates, the cam pushes against a rubbing block on the points, causing them to open and close. When the points are closed, the ignition coil charges, building up energy.

As the points open, this energy is released, creating a high-voltage spark that ignites the fuel in the engine’s cylinders. The opening and closing of the points occur multiple times per second, synchronized with the engine’s revolutions.

It’s important to note that distributor points are mechanical components that can wear down over time due to constant friction and arcing. Dust, oil, and other contaminants can also accumulate on the points, hindering their functionality.

The Impact Of Dirty And Worn-out Points On Engine Performance

Dirty and worn-out distributor points can have a significant impact on engine performance. Over time, the points can become pitted, corroded, or covered in carbon deposits. This can lead to a weak or inconsistent spark, resulting in misfires, reduced power, and poor fuel efficiency.

Here are some common symptoms of dirty or worn-out distributor points:

- Engine misfires or rough idling

- Difficulty starting the engine

- Inconsistent or weak acceleration

- Poor fuel economy

- Increased emissions

Regularly cleaning and inspecting your distributor points is crucial to maintain a reliable ignition system. By keeping the points clean and replacing them when necessary, you can ensure that your engine operates at its best performance.

Tools And Materials Needed

To properly clean points on a distributor, you will need a few essential tools and materials. By having these supplies on hand, you can ensure a thorough and effective cleaning process. In this section, we will discuss the list of tools required and provide an overview of the materials needed to clean distributor points.

List Of Tools Required For Cleaning Distributor Points

When it comes to cleaning distributor points, having the right tools is crucial. Here is a list of tools that you will need:

- Safety goggles: Before you begin the cleaning process, it’s essential to protect your eyes from any debris or sparks that may be generated.

- Gloves: To protect your hands from any chemicals or sharp edges, it’s recommended to wear a pair of gloves throughout the cleaning process.

- Screwdriver: A small screwdriver will be needed to remove the distributor cap and gain access to the points.

- Point file or sandpaper: Use a point file or sandpaper to remove any rust, corrosion, or built-up debris from the points. This will help ensure proper contact and prevent misfires.

- Clean cloth: A clean cloth will be needed to wipe away any residue or dirt from the points and distributor cap.

- Electronic contact cleaner: This specialized cleaner is designed to remove oxidation and other contaminants from electrical components, making it ideal for cleaning distributor points.

Overview Of Materials Needed For The Cleaning Process

In addition to the necessary tools, there are a few materials that you will need to clean the distributor points effectively. These materials include:

- Rubber gloves: Wear rubber gloves to protect your hands when handling any cleaning chemicals or solvents.

- Isopropyl alcohol: Isopropyl alcohol is a commonly used solvent that can help dissolve grease, oil, and other contaminants on distributor points.

- Clean cloth or paper towels: You will need a clean cloth or paper towels to apply the electronic contact cleaner and remove any residue or debris from the points.

- Dielectric grease: After cleaning the points, applying a thin layer of dielectric grease can help prevent future corrosion and ensure a reliable electrical connection.

By gathering these tools and materials before you start the cleaning process, you can make sure that everything is readily available and have a smoother experience. Remember to follow proper safety precautions and consult your vehicle’s manual if needed. Now that you have an understanding of the tools and materials required, let’s move on to the steps for cleaning distributor points.

Step-by-step Guide To Cleaning Distributor Points

Are you experiencing engine performance issues or inconsistent ignition timing in your car? It could be due to dirty distributor points. The distributor points play a crucial role in sending electrical signals to the spark plugs, and over time, they can become corroded or covered in dirt and grime.

In this step-by-step guide, we will walk you through the process of cleaning distributor points to ensure your car runs smoothly and efficiently.

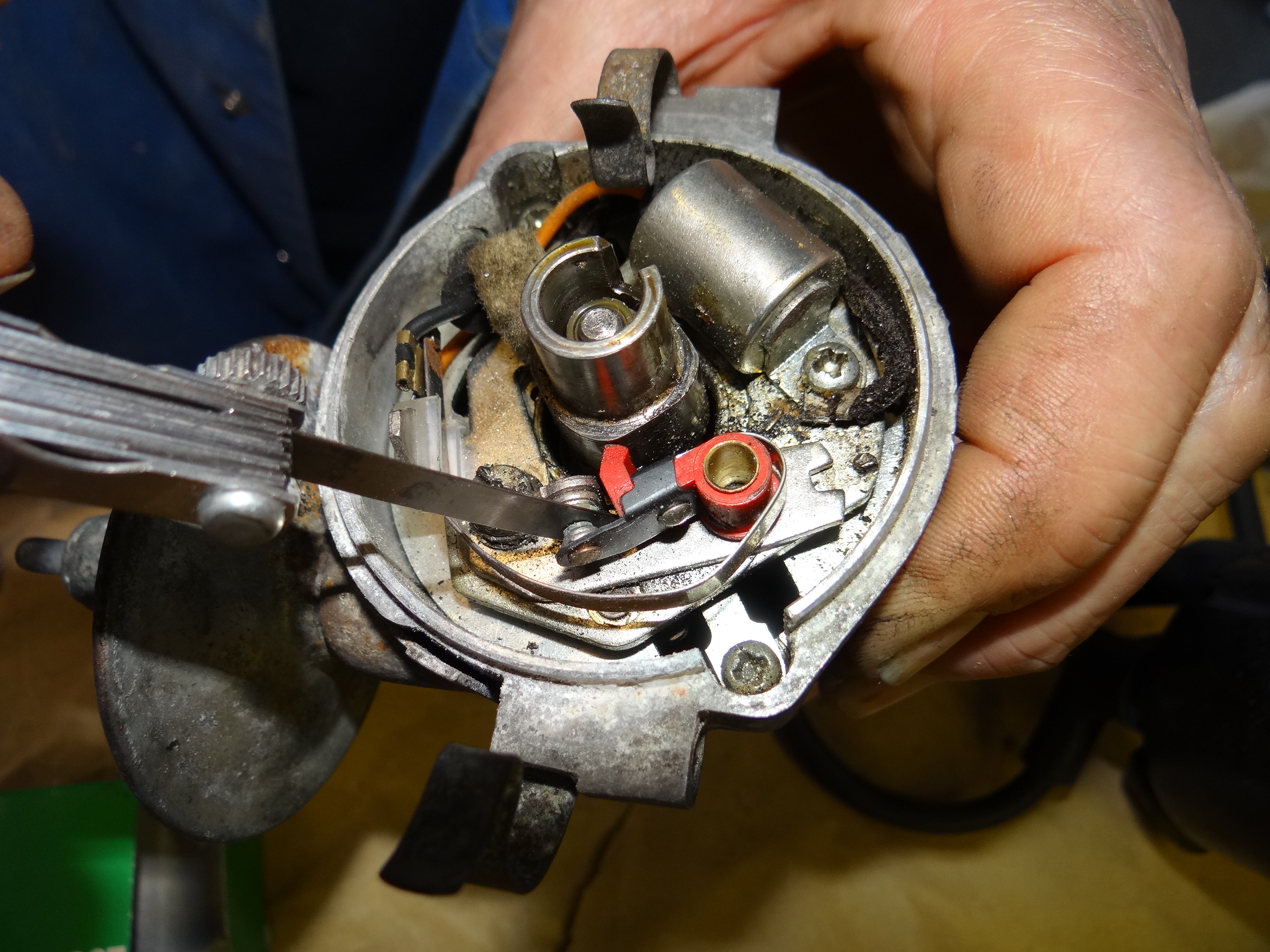

Removing The Distributor Cap

The first step in cleaning distributor points is to remove the distributor cap. This requires the use of a screwdriver or a wrench, depending on the type of cap your vehicle has. Carefully unscrew any bolts or screws securing the cap in place, and gently lift it off, taking care not to damage any wires or connections.

Preparing The Cleaning Solution

Once the distributor cap is removed, it’s time to prepare the cleaning solution. A mixture of warm water and mild detergent can be used to remove dirt and grime from the points. Fill a small container with the solution, making sure it is deep enough to submerge the points in.

Cleaning The Points With A Point File

With the cleaning solution ready, it’s time to clean the distributor points. Using a point file, gently slide it back and forth across the points to remove any built-up debris. Be careful not to apply too much pressure, as this could damage the points. Continue filing until the points appear clean and free from any residue.

Inspecting And Adjusting The Gap

Once the points are clean, it’s important to inspect and adjust the gap. The proper gap ensures optimal performance and ignition timing. Use a feeler gauge to measure the gap between the points, and adjust it if necessary by carefully bending the stationary point. Refer to your vehicle’s manual for the recommended gap measurement.

Reassembling The Distributor

With the points cleaned and the gap adjusted, it’s time to reassemble the distributor. Carefully place the distributor cap back onto the distributor and secure it with the screws or bolts. Ensure each wire is correctly reattached to its respective terminal, using any labels or markings as a guide. Double-check that everything is securely in place before proceeding.

By following this step-by-step guide to cleaning distributor points, you can maintain the efficiency and performance of your car’s ignition system. Regularly cleaning the distributor points will help prevent engine issues and ensure smooth running for years to come.

Credit: www.1020mg.org.uk

Tips For Effective Point Cleaning

Keeping the points on your distributor clean is crucial for maintaining the efficiency and performance of your vehicle’s ignition system. Dirty points can cause misfiring, decreased fuel efficiency, and even engine stalls. To ensure proper cleaning, follow these helpful tips:

Common Mistakes To Avoid During The Cleaning Process

When cleaning the points on your distributor, it’s important to avoid certain common mistakes that can lead to damage or ineffective cleaning. Take note of these mistakes and make sure you don’t fall into these traps:

- Using an abrasive material to clean the points: Avoid using sandpaper or any rough material that can scratch or damage the contact surface of the points. Instead, opt for a soft cloth or fine-grit sandpaper.

- Overlooking the condenser: The condenser plays a vital role in the distributor’s ignition system and should not be neglected during the cleaning process. Clean the condenser carefully, removing any dirt or debris that may have accumulated.

- Skipping lubrication: After cleaning the points, it’s crucial to apply a small amount of dielectric grease or ignition point grease. This lubrication helps to prevent moisture and corrosion, ensuring smooth operation.

Proper Handling Of Distributor Components

When dealing with the distributor components, proper handling is critical to avoid unnecessary damage. Here’s how you can handle the components effectively:

- Disconnect the battery: Before starting any work on the distributor, always disconnect the battery to prevent any accidental electrical shock.

- Use caution when opening the distributor cap: The distributor cap is delicate and can easily crack or break. Gently release the locking clips and lift the cap without applying excessive force.

- Keep track of the order of the wires: Take a picture or make a note of the wire arrangement before removing them from the distributor cap. This way, you won’t mix up the wires during reassembly.

Importance Of Regular Maintenance To Prevent Points From Getting Dirty Quickly

Regular maintenance is vital for preventing points from getting dirty quickly. By implementing a consistent maintenance routine, you can extend the lifespan of your points and ensure a smooth-running ignition system. Here are a few reasons why regular maintenance is essential:

| Benefits of Regular Maintenance |

|---|

| 1. Improved Fuel Efficiency |

| 2. Prevention of Misfiring |

| 3. Increased Longevity of Ignition System |

Regular maintenance includes cleaning the points, inspecting and replacing worn-out parts, and keeping the entire ignition system in optimal condition.

Testing The Ignition System After Cleaning

Testing the ignition system after cleaning the points on a distributor is an essential step to ensure optimal performance of your vehicle. After cleaning the points, it is important to check if the ignition system is functioning correctly, as any issues could lead to poor engine performance or even a breakdown.

In this section, we will explore the importance of testing the system after point cleaning, the steps to perform a spark test, and troubleshooting common issues that may arise.

Importance Of Testing The System After Point Cleaning

Testing the ignition system after cleaning the points is crucial to ensure that the cleaning process was successful and that the electrical connections are working properly. By performing this test, you can identify any issues that might affect the performance of your vehicle’s engine. Ignoring this step could lead to difficulty starting the engine, misfires, or even a complete engine failure.

How To Perform A Spark Test

Performing a spark test is relatively straightforward and can be done with a few simple tools. Here’s a step-by-step guide on how to do it:

- Ensure your vehicle is parked on a level surface and the engine is turned off.

- Locate the ignition coil, which is typically cylindrical in shape, and remove the high-tension wire or spark plug wire.

- If you have a spark plug tester, insert it into the high-tension wire or spark plug wire. Otherwise, you can use a spare spark plug and connect it to the high-tension wire.

- Ground the spark plug tester or the spare spark plug by placing it near a metal surface, such as the engine block.

- Have someone crank the engine while you observe the spark plug tester or the spare spark plug.

- Look for a strong, blue spark jumping across the spark plug gap. This indicates that the ignition system is functioning properly.

- If there is no spark or the spark is weak, there may be a problem with the ignition system, and further troubleshooting is necessary.

Troubleshooting Common Issues Post-cleaning

Even after cleaning the points and performing a spark test, you may encounter certain issues with the ignition system. Here are some common problems that may arise:

| Issue | Possible Causes | Solution |

|---|---|---|

| Weak or intermittent spark | Worn or damaged points, faulty ignition coil, loose connections | Replace points, check and replace ignition coil if necessary, ensure all connections are tight |

| No spark | Blown ignition fuse, faulty ignition switch, defective condenser | Check and replace blown fuse, inspect and replace ignition switch if necessary, replace defective condenser |

| Excessive sparking | Damaged or worn-out ignition coil, incorrect point gap | Replace ignition coil, adjust point gap to manufacturer’s specifications |

By troubleshooting these common issues, you can ensure that your ignition system is in top shape and your vehicle’s engine is running smoothly. Remember to refer to your vehicle’s manual or consult a professional if you encounter any difficulties during the testing and troubleshooting process.

Frequently Asked Questions About How To Clean Points On A Distributor

How Do You Clean A Points Distributor?

To clean a points distributor, follow these steps: Disconnect the battery and remove the distributor cap. Gently clean the points and ignition coil with fine sandpaper or emery board. Use a contact cleaner to remove any debris. Reinstall the distributor cap and reconnect the battery. Start the engine to ensure proper cleaning.

How Are The Breaker Points Cleaned?

To clean breaker points, follow these steps: Turn off the ignition. Remove the distributor cap. Use a fine grit sandpaper or point file to lightly clean the points. Blow away any debris. Reassemble the distributor cap. Regular cleaning helps maintain proper ignition timing.

How Do You Clean Distributor Contacts?

To clean distributor contacts, use a clean cloth or a small brush to remove dirt and debris. Apply contact cleaner to a cotton swab and gently clean the contacts. Ensure they are completely dry before reassembling the distributor. Avoid using excessive force or liquid to prevent damage.

Can You Clean Points With Sand Paper?

Yes, you can clean points with sandpaper. Sandpaper can remove dirt and grime, making the points cleaner and more effective. However, be careful not to damage the points with excessive sanding.

Conclusion

To ensure a smoothly running engine, regular maintenance of the distributor is crucial. By following the simple steps outlined in this blog post, you can effectively clean the points on a distributor. Remember to regularly inspect the points, use the right tools, and take necessary precautions for a safe and successful cleaning process.

With a little effort and care, you can keep your distributor in optimum condition and enjoy a reliable performance from your vehicle. Happy cleaning!

As an Amazon Associate, Cleanestor earns from qualifying purchases at no additional cost to you.