To clean a Midmark autoclave, consult the operator’s manual for specific instructions and use approved cleaners. Regular maintenance includes wiping surfaces and running a full cleaning cycle with a Midmark-approved cleaner.

Maintaining the cleanliness and functionality of medical equipment is vital in healthcare settings, and the Midmark autoclave is no exception. This essential piece of sterilization equipment requires regular cleaning to ensure it operates efficiently and effectively. By adhering to the manufacturer’s guidelines, healthcare professionals can avoid cross-contamination and prolong the lifespan of the autoclave.

A clean autoclave not only meets safety standards but also ensures that medical instruments are properly sterilized, which is crucial for patient care. Engaging in the straightforward process of cleaning and maintaining the autoclave can prevent costly repairs and downtime.

Credit: statimusa.com

Introduction To Autoclave Sterilization

Imagine a world where every medical instrument you encounter is free of harmful bacteria and viruses. That world is made possible through the power of autoclave sterilization, a critical process in healthcare that ensures the safety and sterility of medical tools. Understanding how to maintain this equipment, such as the Midmark Autoclave, is crucial for optimal performance and patient safety.

Defining An Autoclave And Its Importance In Sterilization

An autoclave is a machine used to clean and sterilize medical instruments. It uses steam under high pressure to kill any microorganisms that may cause infection. This is essential in medical settings to prevent the spread of diseases.

Overview Of Midmark Autoclaves Usage In Healthcare Facilities

Midmark Autoclaves are popular in hospitals, dental offices, and other healthcare facilities. They are known for their reliability and efficiency in sterilizing a variety of instruments, making them an indispensable tool for patient care.

Purpose And Benefits Of Regularly Cleaning Autoclaves

- Extends the life of your autoclave

- Ensures consistent performance and sterilization

- Prevents instrument contamination, protecting patients

Understanding The Midmark Autoclave

Clean instruments are crucial in any medical environment. The Midmark Autoclave ensures this. Its design is for sterilizing medical tools efficiently. Knowing how to clean it is vital for all users. Let’s dive into its anatomy, types, and operating principles.

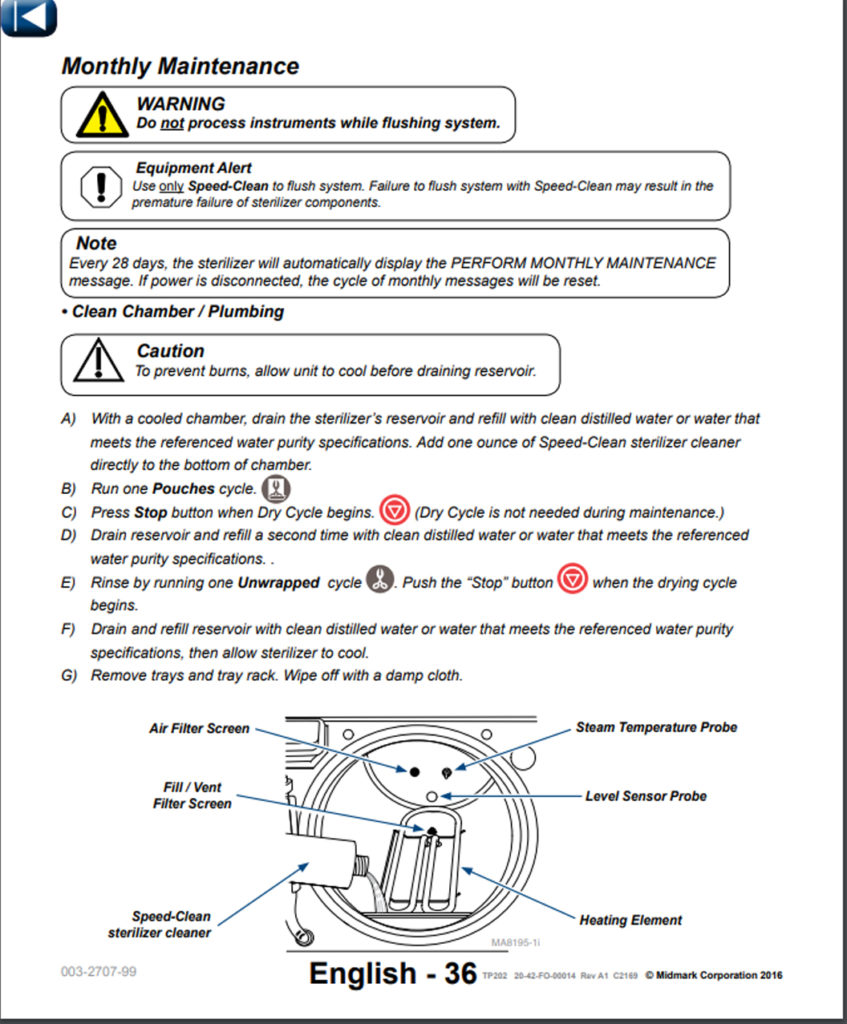

Anatomy Of A Midmark Autoclave: Key Components

A Midmark Autoclave has several crucial parts. Each has a unique role in sterilization. The chamber holds the instruments. A door with a secure seal keeps the steam inside. The reservoir holds water that turns into steam. The control panel sets the cycles. Below is a breakdown of these components:

- Chamber – Where tools are placed for sterilization

- Sealing Door – It locks the chamber

- Water Reservoir – For creating steam

- Control Panel – It programs the sterilization cycles

Types Of Midmark Autoclaves And Their Differences

Midmark Autoclaves come in different models. Each serves distinct needs. Manual autoclaves require user input for operation. Automatic autoclaves start cycles with a button press. Here are their differences:

| Autoclave Type | Operation Mode | Use Case |

|---|---|---|

| Manual Autoclaves | User sets and monitors the cycle | Small clinics, less frequent use |

| Automatic Autoclaves | Pre-programmed cycles | Larger facilities, regular use |

Operating Principles Of Midmark Autoclaves

Midmark Autoclaves use steam for sterilization. They reach high temperatures to kill germs. Pressure inside the chamber increases, penetrating tools for a thorough sterilization. The cycle includes several phases:

- Purging – removes air from the chamber

- Sterilizing – increases temperature and pressure

- Drying – removes moisture from instruments

Proper use ensures clean, sterile instruments every time.

Preparation Before Cleaning

Cleaning your Midmark Autoclave is vital for its performance. Before you start, prepare properly. Proper preparation ensures safety and efficiency. Follow these steps to get your autoclave ready for a thorough clean.

Safety Precautions

Before diving into the cleaning process, it’s crucial to safeguard yourself. Always wear protective gear. This includes gloves and eye protection. Ensure the autoclave’s power is off. Never attempt to clean the device while it’s on or hot. Read the manufacturer’s manual for specific safety tips.

Tools Required For Cleaning

- Soft cloth – for wiping surfaces

- Mild detergent – to clean without damage

- Distilled water – leaves no residue

- Autoclave cleaner – if recommended by the manufacturer

- Soft brush – for scrubbing without scratches

Shutting Down And Cooling Off: Pre-clean Steps

- Turn off the autoclave. This prevents accidents.

- Allow the unit to cool. Check the manual for recommended cooling times.

- Verify that the temperature is safe. Only proceed when the autoclave feels cool to the touch.

Emptying The Chamber And Removing Trays And Racks

Empty the chamber of all instruments and waste material. Check each corner for leftover debris. Remove trays and racks carefully. Soak them in a mixture of mild detergent and water. Wipe with a soft cloth. Rinse with distilled water afterward.

Step-by-step Cleaning Process

Cleaning your Midmark Autoclave is crucial for efficient performance and longevity. This simple guide breaks down the cleaning process, ensuring your autoclave remains in top condition. Follow these steps every few cycles or as recommended by the manufacturer.

Cleaning The Chamber: Methods And Solutions To Use

Over time, the chamber can accumulate deposits from water and materials. Here’s how to properly clean it:

- Turn off and unplug the autoclave.

- Allow the chamber to cool completely.

- Remove any items inside.

- Apply a chamber cleaner designed for autoclaves.

- Use a soft cloth or sponge to wipe the interior.

- Rinse the chamber thoroughly with distilled water.

- Dry with a clean, lint-free cloth.

Dealing With The Trays And Racks: Techniques For Detoxification

Keeping trays and racks clean is key to preventing contamination:

- Remove trays and racks from the autoclave.

- Soak them in a mild detergent solution.

- Scrub with a soft brush to remove debris.

- Rinse with distilled water.

- Allow them to air-dry or use a clean cloth.

Maintaining Door Seals And Filters: How To Keep Them Functional

Proper maintenance of door seals and filters is vital:

- Inspect door gaskets for wear or damage.

- Clean gaskets with a mild soap solution.

- Wipe the seals dry after cleaning.

- Check air filters for blockages.

- Clean or replace filters as required.

Wiping Down External Surfaces: Best Practices For Autoclave Exteriors

Keep the external surfaces of your autoclave clean:

- Use a gentle, non-abrasive cleaner.

- Wipe the surface with a soft cloth.

- Avoid water entering vents or openings.

- Regular cleaning prevents grime build-up.

- Ensure all surfaces are dry before use.

A clean autoclave is a safe and effective one. Follow this guide to maintain your Midmark Autoclave impeccably.

Post-cleaning Measures And Maintenance

Cleaning your Midmark Autoclave is vital for its performance. After scrubbing away grime and germs, take steps to keep it in top shape. This section outlines the essential post-cleaning measures and maintenance needed to ensure your autoclave functions seamlessly.

Drying And Reassembling The Autoclave Post-cleaning

Once cleaning is complete, drying is next. Start by opening the autoclave door to let it air out. Use a clean, dry cloth to wipe any moisture from surfaces. Then, you can begin to reassemble.

Follow these steps to reassemble:

- Place the trays and racks back inside carefully.

- Ensure the door seal is dry and free from debris.

- Close the door securely before the next use.

Correct assembly is crucial for the autoclave to work properly. Double-check all components are in place.

Routine Checks And Calibration After Cleaning

Routine checks keep your autoclave accurate. Calibration is necessary, too. After cleaning, test the autoclave with a few empty cycles.

- Check pressure and temperature gauges for consistency.

- Inspect safety valves to ensure they operate correctly.

If readings seem off, recalibrate. This might require professional assistance.

Maintaining A Cleaning Schedule: When To Clean Your Midmark Autoclave

A strict cleaning schedule extends the life of your equipment. Clean:

| Frequent Use | Moderate Use | Occasional Use |

|---|---|---|

| Daily | Weekly | Monthly |

Remember, a clean autoclave is a reliable one! Stay on top of maintenance to avoid issues.

Troubleshooting Common Issues

Autoclave maintenance is crucial for the longevity of the equipment and the safety of the instruments. Even the robust Midmark autoclave models can experience issues. Fortunately, troubleshooting common issues can be manageable with the right approach.

Identifying And Addressing Residue Buildups

Residue and scale can hinder an autoclave’s performance. Regular maintenance is key.

- Inspect the chamber and trays after cycles.

- Use Midmark-approved cleaning agents.

- Follow the manufacturer’s instructions for cleaning frequency.

Solving Odor Problems In The Autoclave Chamber

Unpleasant smells can indicate a need for thorough cleaning.

- Empty the chamber and clean with a mild detergent.

- Check for and remove any trapped material in the gasket.

- Air out the chamber by leaving the door open after cleaning.

Addressing Autoclave Malfunctions After Inadequate Cleanings

Proper cleaning ensures reliable operation. Inadequate cleanings can cause malfunctions.

| Issue | Action |

|---|---|

| Erratic temperature readings | Inspect sensors and wipe clean. |

| Extended cycle times | Check for clogs and clean exhaust paths. |

| Pressure irregularities | Ensure closing mechanisms are free of debris. |

Conclusion And Best Practices

Cleaning and maintaining a Midmark Autoclave is crucial. This ensures its efficiency. Longevity and reliability depend on proper care.

Summarizing The Importance Of A Clean Autoclave

A clean autoclave is essential for safety and performance. Dirt and debris can cause malfunctions. Regular cleaning reduces these risks.

Highlighting Best Practices For Autoclave Maintenance

Follow the manufacturer’s guide for specific steps.

- Inspect seals and gaskets often.

- Clean with recommended agents only.

- Document maintenance routines.

- Train staff on correct procedures.

These actions prevent costly repairs.

Future Trends In Autoclave Technology And Cleaning Techniques

Technology is always advancing. Future autoclaves will boast automated cleaning. The use of new materials will make autoclaves easier to maintain.

Credit: m.youtube.com

Credit: statimusa.com

Frequently Asked Questions On How To Clean the Midmark Autoclave

How Do You Clean An Autoclave Midmark M11?

Turn off and unplug the Midmark M11 autoclave. Let it cool completely. Clean the chamber and trays with mild detergent, water, and a soft cloth. Dry thoroughly. Wipe the door gasket with a damp cloth. Avoid abrasive materials and harsh chemicals to protect the autoclave surfaces.

How Do You Clean The Inside Of An Autoclave?

To clean an autoclave’s interior, first, turn it off and let it cool. Then, remove any debris, wipe surfaces with a damp cloth, and dry thoroughly. Finally, use an autoclave cleaner following the manufacturer’s instructions. Regular maintenance ensures optimal performance.

How Often Should The Water Be Replaced In The Midmark Autoclave?

Replace the water in your Midmark autoclave after every 20 to 30 cycles to ensure optimal sterilization and performance.

What Solution Is Used To Clean The Autoclave Machine?

To clean an autoclave machine, use a diluted solution of water and a mild, non-abrasive detergent. Regular maintenance with this solution helps ensure effective sterilization.

Conclusion

Proper maintenance of your Midmark Autoclave ensures longevity and reliability. By following the steps outlined, you’ve taken a vital step toward optimal performance. Remember, regular cleaning protects both your equipment and your practice. Let this guide empower you to maintain a pristine autoclave.

Ready for the next clean? Keep this page bookmarked!

As an Amazon Associate, Cleanestor earns from qualifying purchases at no additional cost to you.