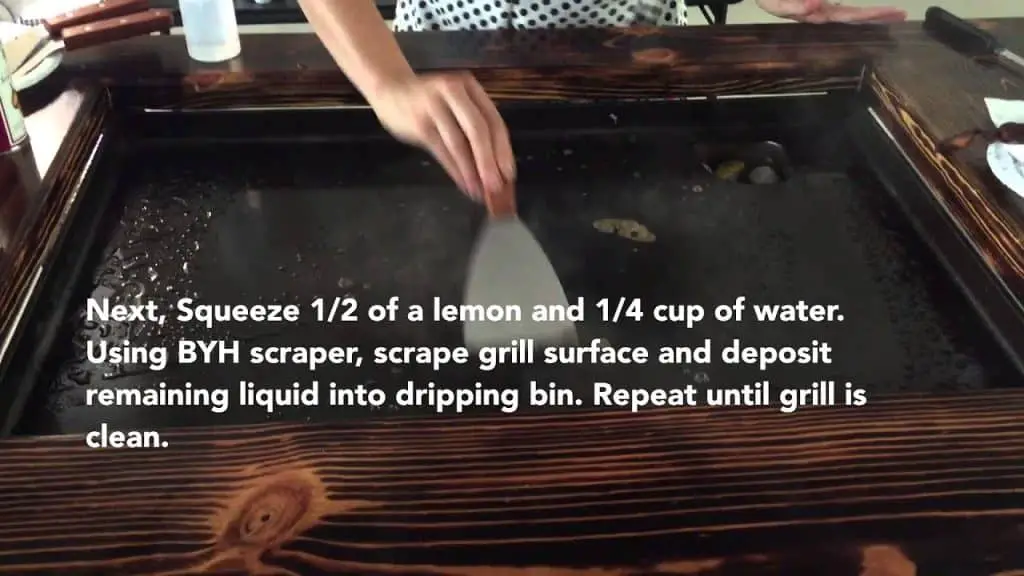

To clean a heat exchanger, follow these steps: first, turn off the power supply and let the equipment cool down. Then, remove any debris or dirt from the surface using a soft brush or vacuum cleaner.

Must-Have Cleaning Essentials For Every Home (Recommended):

- Consistently delivers the same smell, color, and results - every time. For superior and safer cleaning performance, in and around your home.

- Great household product for anything that needs a bright new look! Use it as a cleansing booster with your laundry or dish detergent, as a pH buffer in swimming pools, or for cleaning kitchen surfaces.

Finally, use a solution of warm water and mild detergent to scrub the exchanger, ensuring all areas are thoroughly cleaned. Rinse with clean water and allow it to dry before turning the power back on.

Credit: www.youtube.com

Importance Of Regular Maintenance

Regular maintenance is crucial for the efficient functioning of a heat exchanger. Cleaning the heat exchanger regularly helps to prevent blockages and improve its performance, ensuring optimal heat transfer and energy efficiency.

The Significance Of Cleaning Heat Exchangers

Regular maintenance of heat exchangers is crucial in order to ensure optimal performance and efficiency. Neglecting this important task can lead to a range of issues, including reduced heat transfer efficiency, increased energy consumption, potential equipment breakdowns, and higher operating costs.

By implementing a thorough cleaning regimen, you can improve the overall functionality and longevity of your heat exchanger. Here are some key reasons why cleaning heat exchangers is of utmost importance:

Maximizing Heat Transfer Efficiency:

- Removal of scale, dirt, and debris from heat exchanger surfaces allows for better heat transfer efficiency.

- Clean heat exchanger tubes facilitate the movement of fluids, enhancing heat exchange and preventing them from becoming clogged.

- Cleaner surfaces enable improved contact between the fluids, resulting in more efficient energy transfer.

Reducing Energy Consumption:

- Clean heat exchangers require less energy to achieve the desired heat transfer.

- When the heat exchanger operates at optimal efficiency, less fuel or electricity is required to maintain desired temperatures.

- Lower energy consumption directly translates to cost savings, making regular cleaning a cost-effective maintenance practice.

Preventing Equipment Breakdowns:

- Accumulation of scale, rust, or fouling materials can cause heat exchanger tubes to corrode or deteriorate over time.

- Cleaning helps to remove these damaging substances, preventing potential leaks and equipment failures.

- Regular maintenance eliminates the need for costly repairs or replacements, saving both time and money.

Extending Equipment Lifespan:

- Proper cleaning and maintenance of heat exchangers can significantly prolong their lifespan.

- By preventing the build-up of deposits and corrosive substances, you protect the structural integrity of the equipment.

- Regular cleaning reduces the risk of premature deterioration and extends the overall service life of the heat exchanger.

Ensuring Occupational Safety:

- Regular cleaning and maintenance help to create a safer working environment for personnel.

- Eliminating potentially hazardous substances, such as chemicals, bacteria, or mold, reduces health risks.

- A well-maintained heat exchanger minimizes the chance of leaks or contamination that could jeopardize worker safety.

Regular cleaning is essential for the proper functioning and longevity of heat exchangers. By ensuring optimal performance, reducing energy consumption, and preventing breakdowns, you can save costs and extend the lifespan of your equipment. Additionally, maintaining a safe working environment is vital for the well-being of personnel.

By prioritizing regular cleaning and maintenance, you can keep your heat exchanger operating efficiently and effectively.

Tools And Equipment Needed

To effectively clean a heat exchanger, the necessary tools and equipment include a soft brush or vacuum cleaner, a mild detergent or cleaning solution, a water hose or pressure washer, safety goggles and gloves, and a ladder or platform to reach the exchanger.

Follow these steps for a thorough and safe cleaning process.

Essential Tools For The Cleaning Process

Cleaning a heat exchanger can be a challenging task, but having the right tools makes the process much easier and efficient. Here are the essential tools you’ll need to effectively clean a heat exchanger:

- Scrub brush: A sturdy scrub brush with stiff bristles is essential for removing stubborn dirt and debris from the heat exchanger surfaces.

- Wire brush: This tool is perfect for reaching into narrow crevices and removing any built-up residue or corrosion.

- Vacuum cleaner: A powerful vacuum cleaner will help you remove loose dirt and debris from the heat exchanger, making the cleaning process more effective.

- Compressed air: Using compressed air can help dislodge dust and debris that may be trapped in hard-to-reach areas.

- Safety gloves and goggles: It’s important to protect yourself while cleaning a heat exchanger, so make sure to wear safety gloves and goggles to prevent any accidents.

Equipment Required For Effective Cleaning

Alongside the essential tools, there are a few specific pieces of equipment that are necessary for a thorough heat exchanger cleaning. Consider the following equipment:

- Cleaning solution: Choose a cleaning solution that is suitable for the type of heat exchanger you’re working with. Different materials require specific cleaning agents to ensure effective removal of dirt and contaminants.

- Pressure washer: A pressure washer can help facilitate the cleaning process by delivering a powerful stream of water to remove dirt and debris from the heat exchanger surfaces.

- Condenser tube brush: If you’re cleaning a heat exchanger with condenser tubes, a condenser tube brush is a must-have tool. This specialized brush is designed to thoroughly clean the inside of the tubes, removing any deposits that can impair performance.

- Scraper: A scraper is useful for removing stubborn, caked-on debris from the heat exchanger surfaces. Be sure to choose a scraper that won’t damage or scratch the heat exchanger material.

- Chemical descaler: In some cases, a chemical descaler may be required to remove mineral deposits or scaling on the heat exchanger. This chemical solution helps dissolve and eliminate these stubborn build-ups effectively.

Remember, having the right tools and equipment not only simplifies the cleaning process but also ensures a more thorough and effective clean for your heat exchanger.

Safety Precautions

Learn how to clean a heat exchanger safely with these essential precautions. Follow these guidelines to maintain safety while keeping your heat exchanger clean and functioning efficiently.

Heat exchangers play a crucial role in regulating temperature and ensuring efficient energy transfer in various industrial processes. However, over time, these devices can accumulate dirt, debris, and other contaminants, hindering their performance and potentially leading to costly repairs or replacements.

To prevent such issues, regular cleaning of heat exchangers is paramount. Nonetheless, it’s vital to prioritize safety throughout the cleaning process. This section will outline the key safety precautions to adhere to when cleaning a heat exchanger.

Importance Of Personal Protective Equipment (Ppe)

It’s paramount to prioritize personal safety during the cleaning process by wearing appropriate personal protective equipment (ppe). Here are some reasons why ppe is of utmost importance:

- Eye protection: Shielding your eyes with safety goggles safeguards against potential splashing of cleaning chemicals or debris.

- Respiratory protection: Wearing respiratory masks or respirators protects you from inhaling harmful fumes, dust, or chemicals.

- Hand protection: Gloves provide a barrier against hot surfaces, sharp edges, corrosive substances, or cleaning agents that could cause skin irritation or burns.

- Body protection: Wearing appropriate clothing, such as coveralls or a protective suit, helps shield your body from potential hazards like chemicals or high-temperature surfaces.

Safety Measures To Follow During The Cleaning Process

Cleaning a heat exchanger requires meticulousness and adherence to safety measures to avoid accidents or injuries. Here are some vital safety measures to follow during the cleaning process:

- Power off: Before initiating the cleaning process, ensure that the heat exchanger is completely powered off and disconnected from all energy sources to prevent any potential electrical accidents.

- Lockout/tagout: Implement a lockout/tagout system to inform other personnel that maintenance work is being carried out and prevent any accidental reactivation of the equipment.

- Ventilation: Ensure that the cleaning area is well-ventilated to dissipate any fumes or gases that may be released during the cleaning process.

- Chemical precautions: When using cleaning agents or chemicals, carefully read and follow the manufacturer’s instructions to prevent skin irritation, respiratory issues, or chemical reactions. Store all chemicals in labeled, properly sealed containers.

- High-temperature surfaces: Take caution when dealing with heat exchangers that retain high temperatures, as they can cause burns. Allow sufficient cooling time before commencing the cleaning process.

- Secure footing: Maintain a firm and stable footing while cleaning to prevent slips and falls. If necessary, use non-slip shoes or place anti-slip mats to enhance stability.

- Proper tool usage: Use appropriate tools for the cleaning process and handle them with care. Avoid using damaged or faulty equipment that may compromise safety.

- Team communication: If working with a team, establish clear communication channels to ensure smooth coordination during the cleaning process. Assign roles and responsibilities, and discuss safety procedures beforehand.

- Emergency preparedness: Familiarize yourself with emergency response procedures, such as knowing the location of fire extinguishers, first aid kits, and emergency exits. Be prepared to address any unforeseen incidents promptly and efficiently.

- Training and supervision: Ensure that those involved in the cleaning process have received adequate training and understanding of the safety protocols. Supervision by an experienced professional is beneficial, especially for new team members.

Remember, adhering to these safety precautions is paramount when cleaning heat exchangers. Prioritizing personal protective equipment and adopting proper safety measures will help minimize risks, protect individuals, and ensure a smooth and secure cleaning process.

Inspecting The Heat Exchanger

Inspecting the heat exchanger is essential for maintaining its efficiency. Learn how to clean a heat exchanger effectively to ensure optimal performance and prevent any potential damage.

Identifying Signs Of Dirt And Debris Buildup:

Inspecting the heat exchanger is the first step in ensuring optimal performance and efficiency. By identifying signs of dirt and debris buildup, you can address any potential issues promptly. Here are some key indicators to look out for:

- Visible dirt and debris: Observe the heat exchanger for any visible dirt or debris accumulation. This may appear as layers of dust, rust, or other particles.

- Uneven heat distribution: If you notice certain areas of the heat exchanger are not heating as efficiently as others, it could be indicative of dirt or debris buildup hindering the heat transfer process.

- Reduced airflow: A clogged heat exchanger may result in reduced airflow throughout your hvac system. This can manifest as weak or inconsistent air circulation in your space.

- Unusual sounds: Excessive dirt or debris accumulation can cause unusual sounds coming from the heat exchanger, such as rattling or banging noises. Take note of any unusual auditory cues.

By recognizing these signs, you can take the necessary steps to clean and maintain your heat exchanger, ensuring optimal performance and extending its lifespan.

Assessing The Level Of Contamination:

Once you’ve identified signs of dirt and debris buildup in the heat exchanger, it’s important to assess the level of contamination accurately. This will help you determine the appropriate cleaning approach. Consider the following steps:

- Determine the extent of buildup: Evaluate the thickness and coverage of dirt or debris on the heat exchanger. This will give you an idea of the severity of the contamination.

- Check for blockages: Inspect the heat exchanger for any blockages that may hinder airflow or compromise its functionality. This can be done by visually examining the passages and tubes.

- Measure airflow resistance: Use an airflow meter to measure the resistance caused by the contamination. Higher resistance levels indicate more extensive buildup.

- Consider system performance: Assess how the presence of dirt and debris in the heat exchanger is affecting the overall performance of your hvac system. Look for any significant drops in efficiency or increased energy consumption.

By thoroughly assessing the level of contamination, you can tailor your cleaning approach and ensure effective restoration of your heat exchanger’s efficiency and functionality.

Choosing The Right Cleaning Method

To effectively clean a heat exchanger, it is essential to choose the right cleaning method. This involves considering factors such as the type of fouling, available resources, and environmental impact to ensure optimal performance and longevity.

Cleaning a heat exchanger is crucial to ensuring its optimal performance and extending its lifespan. However, not all heat exchangers are the same, and each requires a different cleaning approach. Determining the appropriate cleaning method based on the type of heat exchanger is essential.

Here are the key factors to consider:

- Tube and shell heat exchangers: These are among the most common types of heat exchangers. When cleaning them, you can choose between chemical cleaning and mechanical cleaning methods. Chemical cleaning involves the use of specific solvents or acids to dissolve deposits and contaminants. On the other hand, mechanical cleaning utilizes brushes, scrapers, or high-pressure water jets to physically remove dirt and build-up.

- Plate heat exchangers: These heat exchangers consist of a series of plates with gaskets in between. Cleaning them requires a method that effectively removes fouling between the plates. Two popular approaches include chemical cleaning and high-pressure water cleaning. Chemical cleaning involves soaking the plates in a solution that dissolves deposits, while high-pressure water cleaning utilizes water jets to blast away fouling.

- Finned tube heat exchangers: These heat exchangers have a large surface area created by the finned tubes. To clean them, it’s important to remove dirt and debris from between the fins. Mechanical brushing or blowing compressed air through the fins are commonly used methods for cleaning finned tube heat exchangers.

- Air-cooled heat exchangers: Unlike liquid-cooled heat exchangers, air-cooled ones require different cleaning methods. Regular maintenance, such as ensuring the fans are clean and functioning properly, is crucial. High-pressure water cleaning or chemical cleaning can be employed to remove dirt from the fins.

Choosing the right cleaning method is crucial for achieving effective heat exchanger cleaning. However, it’s essential to consider other factors as well, such as safety precautions, environmental impact, and manufacturer recommendations. Now, let’s explore the effectiveness of different cleaning methods.

Disassembling The Heat Exchanger

To clean a heat exchanger, it is essential to disassemble it carefully. This process allows for a thorough cleaning of each component, ensuring optimal performance. Proper disassembly and cleaning of the heat exchanger will help maintain its efficiency and prolong its lifespan.

———————————

Maintaining and cleaning the heat exchanger in your hvac system is crucial for efficient performance and longevity. In this step-by-step guide, we will walk you through the process of safely disassembling the unit. By following these instructions, you will be able to properly label and organize the components, ensuring easy reassembly later on.

Step-By-Step Guide To Safely Disassemble The Unit:

- Begin by turning off the hvac system and disconnecting the power supply. Safety should always be your top priority when working with any electrical equipment.

- Locate the access panel on the heat exchanger. It is usually situated near the blower motor housing. Use a screwdriver or the appropriate tool to remove the screws securing the panel.

- Once the panel is removed, you will gain access to the heat exchanger. It may be concealed behind a cover or another panel. Carefully remove any additional screws or fasteners to expose the heat exchanger fully.

- Take note of the position of any wires or connections attached to the heat exchanger. It is essential to document and label these connections accurately for easy reassembly later. You can use colored tape or markers to tag each wire with the corresponding connection point.

- Next, remove the screws or bolts securing the heat exchanger to the hvac system. Depending on the model, there may be multiple attachment points. Ensure you keep track of these fasteners as they are critical for reassembly.

- With the fasteners removed, gently detach the heat exchanger from the hvac system. Take care not to damage any delicate components during this process. If necessary, refer to the manufacturer’s manual for guidance on how to safely handle the unit.

- Once the heat exchanger is separated, inspect it closely for any signs of damage or wear. Look for cracks, corrosion, or excessive buildup of dirt and debris. Note any findings for future reference or potential troubleshooting.

- It is advisable to clean the heat exchanger thoroughly at this point. Refer to our blog post on how to clean a heat exchanger for detailed instructions on how to effectively remove dirt and debris.

- After cleaning, ensure the heat exchanger is completely dry before proceeding with reassembly. Moisture can lead to rust or other issues, so be patient and give it ample time to air dry.

- To organize the disassembled components, use containers or bags labeled with their corresponding names or part numbers. This method will make the reassembly process much more straightforward and help prevent any confusion.

Remember, proper labeling and meticulous organization are crucial when disassembling a heat exchanger. By following this step-by-step guide, you will be well-prepared for the next stage – reassembling the unit.

Cleaning Solutions And Techniques

Learn effective cleaning techniques and solutions for maintaining a heat exchanger. Discover expert tips to keep your equipment in optimal condition without using repetitive terms.

Overview Of Effective Cleaning Solutions

Cleaning a heat exchanger is a crucial task to maintain its efficiency and prolong its lifespan. Various cleaning solutions and techniques can be employed based on the type of heat exchanger and the nature of contaminants. Here is an overview of effective cleaning solutions to keep your heat exchanger in optimal condition:

Different Cleaning Techniques For Specific Types Of Heat Exchangers

When it comes to cleaning heat exchangers, different techniques should be applied depending on the specific type of heat exchanger you have. Here are some cleaning techniques to consider:

- Mechanical cleaning: This technique involves the use of brushes, scrapers, or high-pressure water jets to physically remove debris and fouling from the heat exchanger surfaces. It is effective for lightly fouled heat exchangers.

- Chemical cleaning: Chemical cleaners, such as acids or detergents, can be effective in removing oil, scale, or rust deposits from the heat exchanger. The cleaning solution should be selected based on the type of fouling present and the materials of construction of the heat exchanger.

- Steam cleaning: Steam cleaning utilizes high-temperature steam to remove stubborn deposits from the heat exchanger surfaces. It is effective for removing oily or greasy fouling.

- Ultrasonic cleaning: Ultrasonic cleaning involves immersing the heat exchanger in a cleaning solution and subjecting it to high-frequency sound waves. This technique creates tiny bubbles that collapse, releasing energy and dislodging fouling from the surfaces.

- Hydrodynamic cleaning: This technique uses high-velocity water or air flow to dislodge fouling from the heat exchanger surfaces. It is particularly effective for removing heavy deposits or hard-to-reach fouling.

Remember, applying the right cleaning technique is essential to avoid damaging the heat exchanger. Always refer to the manufacturer’s guidelines and seek professional assistance if needed.

Cleaning a heat exchanger requires the use of appropriate cleaning solutions and techniques to optimize its performance. By following the right cleaning practices, you can ensure that your heat exchanger operates efficiently and maintain its longevity.

Manual Cleaning

Learn how to effectively clean a heat exchanger with manual cleaning methods. Our step-by-step guide provides easy-to-follow instructions for maintaining the efficiency and longevity of your heat exchanger.

Cleaning a heat exchanger is an essential maintenance task to ensure its optimal performance and longevity. While there are various methods for cleaning a heat exchanger, manual cleaning remains one of the most effective approaches. This technique involves physically removing stubborn deposits and residue from the heat exchanger’s surface.

In this section, we will provide step-by-step instructions for the manual cleaning process as well as techniques to tackle those pesky deposits.

Step-By-Step Instructions For Manual Cleaning Process:

- Prepare the work area: Before you start cleaning, make sure to gather all the necessary tools and materials. Clear the surrounding area to create a safe and unobstructed workspace.

- Turn off the heat exchanger: Ensure that the heat exchanger is completely shut off and disconnected from the power source. This is crucial for safety reasons and to avoid any potential accidents.

- Inspect the heat exchanger: Carefully examine the heat exchanger for any visible signs of damage or wear. If you notice any issues, it’s important to address them before proceeding with the cleaning process.

- Remove loose debris: Use a soft brush or compressed air to gently remove any loose debris or dust from the surface of the heat exchanger. This will make the manual cleaning process more effective.

- Apply cleaning solution: Depending on the type of deposits you need to remove, choose a suitable cleaning solution. Apply the solution directly to the affected areas, ensuring thorough coverage.

- Scrub with a brush: Using a soft brush with nylon bristles, scrub the surface of the heat exchanger in a circular motion. Pay extra attention to areas with stubborn deposits or residue.

- Rinse with water: Once you have thoroughly scrubbed the heat exchanger, rinse it with water to remove the cleaning solution and dislodged deposits. Use a hose or water spray to ensure proper rinsing.

- Inspect and repeat if necessary: After rinsing, inspect the heat exchanger to ensure that all deposits have been removed. If necessary, repeat the cleaning process to achieve the desired cleanliness.

Techniques To Remove Stubborn Deposits And Residue:

- Vinegar solution: Create a mixture of equal parts vinegar and water to effectively dissolve mineral deposits and scale. Apply the solution and scrub with a brush before rinsing.

- Chemical cleaners: Depending on the type of deposit or residue, specific chemical cleaners may be required. Follow the manufacturer’s instructions for application and ensure proper ventilation during use.

- High-pressure cleaning: For more stubborn deposits, consider using a pressure washer to blast away the buildup. Adjust the pressure accordingly to avoid damaging the heat exchanger.

- Mechanical methods: In some cases, manual scraping or scraping with a wooden or plastic tool may be necessary to remove hardened deposits. Be cautious not to scratch or damage the heat exchanger’s surface.

Remember, regular cleaning and maintenance of your heat exchanger will contribute to its efficiency and extend its lifespan. By following these step-by-step instructions and applying the appropriate techniques for stubborn deposits, you can ensure optimal heat transfer and maximum performance from your heat exchanger.

Mechanical Cleaning Methods

Clean a heat exchanger using mechanical cleaning methods. These methods involve physical tools and techniques to remove dirt, scale, and debris from the heat exchanger’s surfaces, ensuring efficient heat transfer and optimal performance.

Exploring Mechanical Cleaning Options

Cleaning a heat exchanger is crucial to maintain its efficiency and extend its lifespan. When it comes to mechanical cleaning methods, there are various options to consider. Here, we will explore some of the most efficient methods that can be employed to clean a heat exchanger effectively:

- Utilizing brushes: Using brushes to clean a heat exchanger is an effective mechanical method. Different types of brushes, such as nylon or wire, can be used depending on the level of dirt and the exchanger’s material. Brushes are ideal for removing loose debris and light scaling.

- Scrapers: Scrapers are handy tools for dislodging tough and stubborn deposits from the surface of a heat exchanger. They can efficiently remove heavy scaling and stubborn deposits that brushes can’t reach. However, caution must be exercised when using scrapers to avoid damaging the heat exchanger’s surface.

- Pressure washers: A pressure washer can be a powerful tool for cleaning a heat exchanger quickly and thoroughly. By utilizing high-pressure water jets, it can remove dirt, debris, and scaling deeper within the exchanger. Pressure washers are particularly effective for large heat exchangers with extensive surface area.

- Chemical cleaning in conjunction with mechanical methods: In certain cases, combining chemical cleaning with mechanical methods can yield exceptional results. Applying appropriate chemicals can help loosen stubborn deposits, making it easier for brushes, scrapers, or pressure washers to clean the exchanger more effectively.

Mechanical cleaning methods provide efficient ways to clean heat exchangers. By utilizing brushes, scrapers, or pressure washers, it becomes possible to remove debris, scaling, and deposits effectively, restoring the heat exchanger’s optimal performance. However, it is crucial to choose the appropriate method based on the type of deposit and the exchanger’s material to avoid causing damage.

Chemical Cleaning

Clean your heat exchanger effectively with chemical cleaning techniques. Remove dirt and debris to improve heat transfer efficiency and ensure the smooth operation of your equipment.

Understanding The Process Of Using Chemicals For Cleaning:

- Chemical cleaning plays a crucial role in effectively removing dirt, scaling, and corrosion from a heat exchanger. It involves the use of specially formulated chemicals to break down deposits and maintain the efficiency of the heat exchanger.

- The chemical cleaning process typically consists of three stages: Pre-cleaning, main cleaning, and post-cleaning. Each stage requires careful planning and execution to ensure effective results.

- During pre-cleaning, the heat exchanger is flushed with a suitable cleaner to remove loose debris and contaminants. This step prepares the exchanger for the main cleaning process.

- The main cleaning process involves the application of chemicals specifically designed to dissolve and remove stubborn deposits. These chemicals may include acids, alkaline solutions, or specialty products, depending on the nature of the deposits.

- The chemicals are circulated through the heat exchanger either by using a chemical circulation pump or by filling the exchanger with the cleaning solution and allowing it to soak for a specified duration. This allows the chemicals to penetrate and dissolve the deposits effectively.

- After the main cleaning process, the heat exchanger is thoroughly rinsed with water to remove any residual chemicals and contaminants. This step is crucial to ensure the safe operation of the exchanger.

- Proper disposal of used chemicals is vital to ensure environmental compliance. It is important to follow local regulations and guidelines when disposing of chemical waste.

Precautions And Guidelines For Safe Chemical Cleaning:

- Chemical cleaning should only be performed by trained professionals who are well-versed in the safe handling and application of cleaning chemicals. Safety should always be the top priority.

- Before initiating chemical cleaning, perform a thorough inspection of the heat exchanger to identify any damaged or corroded areas. Repair or replace any components as necessary to ensure the process goes smoothly.

- Use appropriate personal protective equipment (ppe) such as gloves, safety glasses, and protective clothing while handling cleaning chemicals to prevent contact with the skin or eyes.

- Adequate ventilation is crucial during chemical cleaning to minimize exposure to fumes and vapor. Make sure to work in well-ventilated areas or use exhaust fans to remove any potentially harmful gases.

- Follow the manufacturer’s instructions and guidelines for the proper dilution and application of cleaning chemicals. Improper concentrations or methods can lead to ineffective cleaning or damage to the heat exchanger.

- Always test the cleaning solution on a small, inconspicuous area of the heat exchanger before performing a full-scale cleaning. This helps to ensure compatibility and avoid any adverse reactions or damage.

- Be cautious with acid-based cleaners, as they can corrode certain metals. If the heat exchanger contains materials susceptible to acid attack, select an appropriate alternative cleaner.

- After completing the chemical cleaning process, thoroughly flush the heat exchanger with clean water and perform a visual inspection to ensure no traces of chemicals are left behind.

- Document the cleaning process, including the chemicals used, concentrations, duration of cleaning, and any observations made during the process. This information will be valuable for future reference and maintenance.

Remember, chemical cleaning of heat exchangers requires expertise and adherence to safety guidelines. Always consult with professionals or seek guidance from manufacturers to ensure the process is carried out effectively and safely.

Reassembling The Heat Exchanger

Learn how to clean a heat exchanger by following our step-by-step guide on reassembling the unit. This will ensure a thorough cleaning process and optimal performance for your heat exchanger.

Properly Assembling The Components:

After successfully cleaning the heat exchanger, the next crucial step is to reassemble its components correctly. This ensures a secure and functional heat exchanger unit, allowing it to perform at its best. Here are the steps you need to follow to properly assemble the heat exchanger:

- Start by organizing the cleaned components: Gather all the cleaned parts of the heat exchanger and ensure they are free of any debris or contaminants. Lay them out on a clean, dry surface for easy access during reassembly.

- Inspect the gaskets and seals: Carefully examine the gaskets and seals for any signs of wear or damage. If they appear worn out, it’s essential to replace them before proceeding with the reassembly process. Using damaged gaskets or seals can lead to leaks and reduced efficiency.

- Align the heat exchanger tubes or plates: If your heat exchanger consists of tubes or plates, ensure they are correctly aligned before proceeding. This ensures a smooth flow of fluid and optimal heat transfer within the unit. Check for any misalignment or bent tubes and rectify them if necessary.

- Apply a suitable lubricant: Before attaching the components, apply a suitable lubricant to enhance the ease of assembly. This prevents friction and damage during the process. Ensure you follow the manufacturer’s recommendations for the appropriate lubricant to use.

- Securely attach the components: Begin by attaching the tubes, plates, or other components according to the heat exchanger’s design. Use the appropriate fasteners or clamps as specified by the manufacturer. Tighten them gently but firmly, ensuring a secure connection without over-tightening and risking damage.

- Install new gaskets and seals: If you had to replace any gaskets or seals, carefully position them in their designated places. Make sure they are properly aligned and seated before proceeding with the reassembly.

- Double-check the connections: Once all the components are attached, carefully inspect each connection point to ensure it is secure. Tighten any loose connections that are detected. Pay particular attention to areas where leaks are most likely to occur, such as the tube-sheet joints or plate gaskets.

- Reattach any auxiliary devices: If your heat exchanger has auxiliary devices like sensors, valves, or pressure gauges, reinstall them in their designated locations. Ensure they are properly connected, and any electrical or hydraulic connections are secure.

- Clean the exterior: After reassembling the heat exchanger, clean its exterior to remove any dirt or fingerprints that may have accumulated during the process. A clean exterior not only looks aesthetically pleasing but also helps with the overall maintenance and longevity of the unit.

- Perform a final inspection: Before putting the heat exchanger back into service, conduct a comprehensive final inspection. Check for any loose components, leaks, or abnormalities. Rectify any issues found before putting the unit into operation.

By following these steps, you can ensure the proper reassembly of your heat exchanger, guaranteeing its efficiency and functionality.

Testing And Quality Assurance

Learn how to effectively clean a heat exchanger with these expert tips on testing and quality assurance. Ensure optimal performance and energy efficiency by following these guidelines for maintaining your heat exchanger.

After successfully cleaning a heat exchanger, it is crucial to conduct post-cleaning checks and tests to ensure its cleanliness and efficiency. This step is vital to guarantee optimal performance and prevent any potential issues. Here are the key aspects to consider during the testing and quality assurance process:

Verifying The Cleanliness Of The Heat Exchanger:

- Conduct a visual inspection: Carefully examine the interior and exterior surfaces of the heat exchanger. Look for any remaining dirt, debris, or scale that may have been missed during the cleaning process.

- Use a flashlight or bore scope: In some cases, visibility can be limited, especially when dealing with complex heat exchanger designs or hard-to-reach areas. Utilize a flashlight or a bore scope to inspect the internal components thoroughly.

- Check for any remaining deposits: Pay attention to areas that are prone to deposit buildup, such as tubes, fins, and passageways. Make sure there are no blockages or obstructions that could hinder proper heat transfer.

- Assess the surface condition: Inspect the surfaces for any signs of corrosion, pitting, or damage. Address these issues promptly to maintain the longevity of the heat exchanger.

Ensuring The Efficiency Of The Heat Exchanger:

- Temperature and pressure measurements: Measure the inlet and outlet temperatures and pressures to ensure they fall within the specified range. Any discrepancies could indicate a malfunction or inefficiency.

- Log system performance data: Keep a record of temperature differentials, flow rates, and overall system efficiency. By monitoring this data over time, you can identify any changes or patterns that might require attention.

- Analyze heat transfer rates: Evaluate the heat transfer coefficient and compare it to the manufacturer’s specifications. An inefficient heat exchanger may have a lower heat transfer rate, indicating that further cleaning or maintenance is necessary.

- Perform flow testing: Assess the flow rate through the heat exchanger and check for uniform distribution. Variations in flow may lead to hotspots or inadequate heat transfer, so it’s crucial to maintain consistent flow throughout the system.

Conducting Post-Cleaning Checks And Tests:

- Implement non-destructive testing (ndt): Ndt methods, such as ultrasonic testing or dye penetrant inspection, can detect any internal defects or leaks. These techniques help ensure the integrity of the heat exchanger and minimize the risk of failures.

- Pressure testing: Pressurize the heat exchanger with air or water to evaluate its structural integrity. This test can identify potential leaks or weak points that could compromise performance.

- Performance benchmarking: Compare the heat exchanger’s post-cleaning performance with its initial baseline measurements. This benchmarking allows for accurate assessment of the cleaning process and provides valuable insights into the overall effectiveness of the maintenance routine.

Remember, by conducting comprehensive tests and quality assurance checks, you can confidently verify the cleanliness and efficiency of the heat exchanger. This diligent approach will help optimize its performance and extend its lifespan, ensuring reliable operation going forward.

Maintaining A Cleaning Schedule

Maintaining a cleaning schedule is crucial for the efficient functioning of a heat exchanger. Regular cleaning ensures optimal performance and extends the lifespan of the equipment. Proper cleaning techniques, such as using appropriate cleaning agents and removing debris, help prevent blockages and maintain the heat exchanger’s efficiency.

Establishing A Regular Cleaning Schedule

Regular cleaning of your heat exchanger is essential to maintain its efficiency and protect it from damage. By establishing a consistent cleaning schedule, you can ensure that your heat exchanger operates at its optimal level for an extended period. Here are a few steps you can take to establish a regular cleaning routine:

- Review manufacturer’s guidelines: Start by referring to the manufacturer’s recommendations for cleaning and maintenance. They often provide specific instructions tailored to your heat exchanger model.

- Consider the operating environment: Assess the conditions in which your heat exchanger operates. Factors such as dust levels, humidity, and chemical exposure may influence the cleaning frequency needed.

- Create a cleaning calendar: Develop a cleaning calendar that outlines the frequency and specific tasks for each cleaning session. This will help you stay organized and ensure regular maintenance.

- Assign responsibilities: Determine who will be responsible for cleaning the heat exchanger. It could be an in-house maintenance technician or outsourced to a professional service provider. Clearly communicate the tasks and expectations to avoid any confusion.

- Document cleaning activities: Keep a record of each cleaning session, including the date and details of the tasks performed. This documentation will help you track the frequency of cleanings and identify any patterns that may lead to maintenance improvements.

- Monitor performance: Regularly evaluate the performance of your heat exchanger to identify signs of inefficiency or potential issues between cleanings. This proactive approach will enable you to address any concerns before they become more significant problems.

Benefits Of Routine Maintenance

Maintaining a regular cleaning schedule for your heat exchanger offers several benefits. Here are a few reasons why routine maintenance is crucial:

- Optimal heat transfer: Regular cleaning prevents the buildup of dirt, debris, and contaminants that can obstruct heat transfer. By ensuring efficient heat transfer, your heat exchanger will operate at its maximum potential, resulting in energy savings and improved performance.

- Extended equipment lifespan: Cleaning the heat exchanger regularly helps to prevent corrosion, scaling, and fouling. This extends the lifespan of your equipment and reduces the need for costly repairs or premature replacements.

- Improved air quality: A clean heat exchanger ensures that the air flowing through it remains uncontaminated. This helps maintain indoor air quality, which is essential for the health and well-being of occupants.

- Cost savings: By investing in regular maintenance, you can avoid significant repair or replacement costs that may arise from neglecting your heat exchanger’s cleaning needs. Additionally, a well-maintained heat exchanger operates more efficiently, resulting in lower energy consumption and reduced utility bills.

Establishing a regular cleaning schedule for your heat exchanger is vital to maintain its efficiency and ensure its longevity. By adhering to a consistent cleaning routine and reaping the benefits of routine maintenance, you can enjoy optimal heat transfer, extended equipment lifespan, improved air quality, and significant cost savings.

Frequently Asked Questions Of How To Clean A Heat Exchanger

How Often Should A Heat Exchanger Be Cleaned?

It is recommended to clean a heat exchanger at least once a year to ensure optimal performance and prevent any build-up of debris or sediment that could impede its efficiency.

What Are The Benefits Of Cleaning A Heat Exchanger?

Cleaning a heat exchanger can improve its efficiency, resulting in energy savings and reduced operating costs. It also helps prolong the lifespan of the equipment, prevents potential breakdowns, and ensures better indoor air quality.

What Are The Common Methods For Cleaning A Heat Exchanger?

Common methods for cleaning a heat exchanger include chemical cleaning, mechanical cleaning, and high-pressure water cleaning. The method used depends on the type and condition of the heat exchanger and should be performed by a professional to ensure safe and effective results.

How Long Does It Take To Clean A Heat Exchanger?

The time required to clean a heat exchanger varies depending on its size, complexity, and level of dirt or debris. Generally, it can take a few hours to a full day for professional technicians to thoroughly clean and inspect a heat exchanger.

Conclusion

Maintaining a clean heat exchanger is crucial for its optimal performance and longevity. Regular cleaning and maintenance not only improve energy efficiency but also reduce the risk of system breakdowns and costly repairs. By following the simple steps outlined in this blog post, you can effectively clean your heat exchanger and ensure its efficient operation.

Remember to wear protective gear, use appropriate cleaning solutions, and take necessary precautions before starting the cleaning process. Regular inspection and cleaning of your heat exchanger will help extend its lifespan and save you money in the long run. Don’t neglect this essential maintenance task and enjoy the benefits of a clean and well-functioning heat exchanger that keeps your home comfortable all year round.