To clean the distiller boiling chamber, begin by disconnecting the power and allowing it to cool. Remove any remaining water and debris, then wipe the chamber with a mild detergent and water solution. Rinse and dry thoroughly before reconnecting and using the distiller again.

Keeping your distiller boiling chamber clean is crucial for maintaining the quality and functionality of your distillation process. Over time, mineral deposits, residue, and other impurities can build up, compromising the efficiency and performance.

Regular cleaning not only ensures optimal performance but also extends the lifespan of your distiller. In this guide, we will provide you with simple yet effective steps to clean your distiller boiling chamber, ensuring the production of clean and pure distilled water.

By following these steps, you can easily maintain the cleanliness of your distiller and enjoy the benefits of fresh, pure water for years to come.

Credit: waterdistillers.com

The Importance Of Cleaning The Distiller Boiling Chamber

Cleaning the distiller boiling chamber is an essential step in maintaining the optimal performance of your distiller. Neglecting this task can lead to the buildup of impurities and contaminants, compromising the quality of your distilled water. Regular cleaning not only ensures the longevity of your distiller but also contributes to the health and safety of those using the water produced.

Let’s explore the reasons why cleaning the distiller boiling chamber is so crucial:

Prevents Buildup And Ensures Optimal Performance

- Remove mineral deposits: Over time, minerals from the water can accumulate in the boiling chamber, forming crusty deposits. Cleaning the chamber prevents these deposits from affecting the efficiency and effectiveness of the distiller.

- Eliminate bacteria and mold: Warm and moist environments can promote the growth of bacteria and mold. Regular cleaning helps eliminate these potentially harmful microorganisms, ensuring the purity of your distilled water.

- Prevents scale formation: Hard water contains minerals that can form scale inside the boiling chamber. Scale buildup can obstruct the heat transfer process and reduce the distiller’s efficiency. Cleaning the chamber prevents scale formation, thus maintaining optimal performance.

- Enhances taste and odor: Contaminants and impurities can affect the taste and odor of your distilled water. Cleaning the boiling chamber helps remove any residues or buildup, resulting in cleaner, purer water.

Regularly cleaning the distiller boiling chamber is an essential maintenance task that should not be overlooked. By preventing buildup and ensuring optimal performance, you can enjoy pure, great-tasting water while prolonging the lifespan of your distiller.

Tools Needed For Cleaning

Cleaning your distiller boiling chamber is essential for maintaining the efficiency and longevity of your distillation unit. To get started, gather the following tools and supplies:

- Cleaning brush: A soft-bristle brush will help remove any residue or buildup inside the boiling chamber.

- Microfiber cloth: This gentle cloth is perfect for wiping down the exterior of the boiling chamber.

- Distilled water: Using distilled water for cleaning will prevent any mineral deposits from accumulating.

- White vinegar: Vinegar is an excellent natural cleaner that can dissolve stubborn stains and disinfect the boiling chamber.

- Mild dish soap: Opt for a mild dish soap to clean the boiling chamber thoroughly.

- Water container: You’ll need a container to hold the distilled or clean water when you’re cleaning the boiling chamber.

Now that you have gathered all the necessary supplies, you’re ready to tackle the cleaning process. Follow the next steps to ensure a successful cleaning session.

Step-By-Step Guide To Cleaning The Distiller Boiling Chamber

Clean the distiller boiling chamber with ease by following this step-by-step guide. Maintain the cleanliness and efficiency of your distiller by removing dirt and residue from the chamber using simple cleaning techniques. Keep your distiller in top shape for optimal performance.

Safety Precautions

- Before beginning the cleaning process, ensure the distiller is completely disconnected from power to avoid any potential electrical hazards.

- Wear protective gloves to protect your hands from any chemical residues and to maintain good hygiene during the cleaning process.

Disconnecting The Distiller From Power

- Locate the power source of the distiller and unplug it from the electrical outlet.

- Double-check to ensure the distiller is completely powered off before proceeding with the cleaning process.

Draining And Removing Any Remaining Water

- If there is any remaining water in the boiling chamber, carefully drain it by following these steps:

- Locate the drain valve or plug at the bottom of the chamber.

- Attach a hose or place a container beneath the drain to collect the water.

- Open the drain valve or remove the plug to let the water flow out completely.

Removing Residue And Buildup

To effectively clean the distiller boiling chamber and remove any residue or buildup, follow these steps:

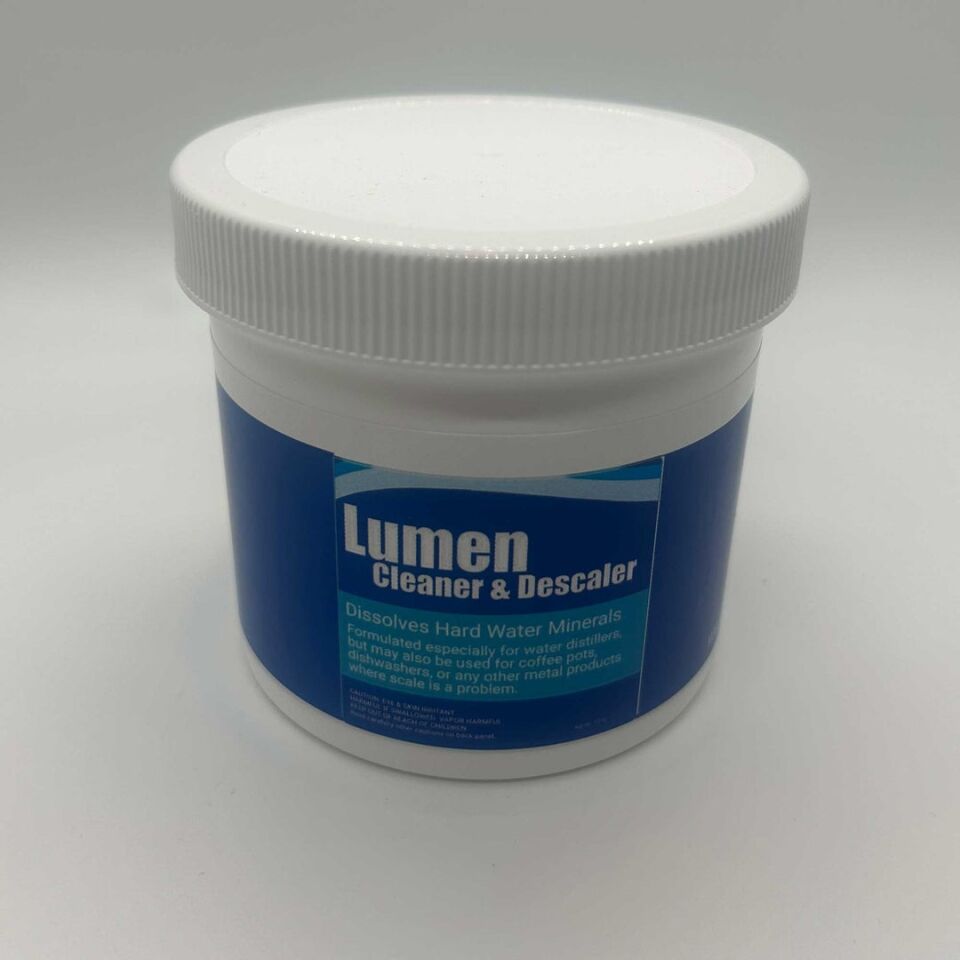

- Mix a cleaning solution suitable for your distiller, using manufacturer-recommended products or a combination of vinegar and water.

- Apply the cleaning solution to a soft cloth or sponge, ensuring it is damp but not dripping.

- Gently scrub the interior walls and surfaces of the boiling chamber to remove any residue or buildup.

- Pay extra attention to any stubborn areas by gently applying more pressure during scrubbing.

- Rinse the chamber thoroughly with clean water to remove any traces of the cleaning solution.

Cleaning The Exterior Of The Chamber

It is important to clean the exterior of the distiller boiling chamber to maintain its overall cleanliness:

- Using a clean cloth or sponge and mild soap, gently wipe down the exterior surfaces of the chamber.

- Pay attention to any visible dirt or stains, giving them extra attention during cleaning.

- Rinse the exterior surfaces with clean water and wipe them dry.

Drying The Chamber Thoroughly

After cleaning the distiller boiling chamber, it is crucial to ensure it is properly dried before reassembling and using it again:

- Use a clean, dry cloth or towel to wipe the interior and exterior surfaces of the chamber.

- Leave the chamber in a well-ventilated area to air dry completely.

- Check that there is no moisture remaining before proceeding to reassemble the distiller.

Remember, following these step-by-step instructions will help you effectively clean the distiller boiling chamber, ensuring its longevity and performance. Stay safe by adhering to the proper safety precautions throughout the cleaning process.

Tips For Effective Maintenance And Prevention

Maintaining and cleaning the distiller boiling chamber is essential for effective operation. Learn effective tips to keep your distiller boiling chamber clean and prevent any issues in the long run.

Regular Cleaning Schedule

- It is important to establish a regular cleaning schedule for the distiller boiling chamber to ensure its optimal performance and longevity.

- Clean the chamber at least once every three months to avoid the buildup of mineral deposits and impurities.

- Begin by disconnecting the distiller from the power source and allowing it to cool down completely.

- Use a soft cloth or sponge dampened with a mixture of water and mild detergent to wipe the inside of the boiling chamber.

- Pay extra attention to the heating element and any crevices where debris might accumulate.

- Rinse the chamber thoroughly with clean water to remove any soap residue.

- Allow the chamber to dry completely before reassembling and reconnecting the distiller.

Using Distilled Water

- Using distilled water in the distiller boiling chamber can help prevent the formation of mineral deposits.

- Do not use tap water or water from unknown sources, as they can contain impurities and minerals that can accumulate within the chamber.

- Distilled water is free from impurities and minerals, making it ideal for use in the distiller.

- Always ensure that the water used is free from contaminants, as they can affect the distiller’s performance and lifespan.

Checking For Any Signs Of Damage

- Regularly inspect the distiller boiling chamber for any signs of damage or wear.

- Look for cracks, rust, or any other visible signs of deterioration.

- Check the gasket or seal around the chamber to ensure it is intact and functioning properly.

- Any damage or deterioration should be addressed immediately to prevent further issues and maintain the distiller’s efficiency.

- Consult the manufacturer’s instructions for guidance on how to replace or repair any damaged components.

By following these tips for effective maintenance and prevention, you can ensure that your distiller boiling chamber remains clean, efficient, and in optimal working condition for a long time. Regular cleaning and the use of distilled water will protect the chamber from mineral deposits and impurities, while checking for signs of damage will help you address any issues promptly.

Remember to establish a cleaning schedule and follow the manufacturer’s guidelines for best results.

Troubleshooting Common Issues With The Distiller Boiling Chamber

Clean your distiller boiling chamber easily with these troubleshooting tips. Say goodbye to common issues and keep your distiller running smoothly.

Identifying Potential Problems

- High-pitched humming noise: It could indicate a malfunctioning fan. Check if the fan blades are clean and clear of debris. If the problem persists, contact the manufacturer for assistance.

- Leaking water: Inspect the water tank and ensure the cap is tightly sealed. If the issue persists, consider replacing the gasket or contacting the manufacturer.

- No power: Check if the distiller is properly connected to a power source. If it still doesn’t turn on, try a different outlet or consult an electrician.

Low Water Level

- Check the water level indicator: Ensure that the distiller is not operating with a low water level. Refill the boiling chamber with clean water if necessary.

- Inspect the water inlet valve: Make sure the valve is open and free from any blockages, allowing water to flow into the boiling chamber.

- Clean the water level sensor: If the sensor is dirty or covered in scale, gently clean it to ensure accurate water level detection.

Overheating

- Examine the thermostat: Ensure that the thermostat is set to the appropriate temperature for distillation. If it is too high, reduce the setting and monitor the temperature.

- Clear the ventilation openings: Dust or lint accumulation can obstruct the airflow and cause overheating. Carefully clean the ventilation openings to promote proper cooling.

- Avoid overloading the distiller: Distilling excessive amounts of water beyond the recommended capacity can lead to overheating. Follow the manufacturer’s guidelines for optimal usage.

Strange Odors

- Clean the boiling chamber: Deposits or residue from distillation can contribute to unpleasant odors. Regularly clean the boiling chamber with a vinegar or citric acid solution to eliminate smells.

- Replace or clean the carbon filter: If your distiller has a carbon filter, it may need replacement or cleaning to remove odorous impurities.

- Check for electrical issues: Malfunctioning components can produce unusual smells. If you suspect an electrical problem, contact a professional technician for diagnosis and repair.

Remember to consult the manufacturer’s manual for specific troubleshooting steps and always prioritize safety when cleaning or handling electrical equipment.

Additional Steps For Deep Cleaning And Intensive Maintenance

Maintaining your distiller boiling chamber is essential for ensuring optimal performance and longevity of your distiller. While regular cleaning is sufficient for most cases, undertaking additional steps for deep cleaning and intensive maintenance can be beneficial. In this section, we will discuss how to disassemble the chamber, clean individual parts, and reassemble the chamber to ensure thorough maintenance.

Disassembling The Chamber

To begin the deep cleaning process, follow these steps to disassemble the distiller boiling chamber:

- Start by turning off and unplugging the distiller to ensure safety.

- Remove the lid of the boiling chamber carefully.

- Locate the screws or clips that hold the chamber in place and use the appropriate tools to loosen and remove them.

- Gently separate the boiling chamber from the base unit, taking care not to damage any internal components.

- Place the disassembled parts on a clean and dry surface and ensure proper organization to avoid confusion during reassembly.

Cleaning Individual Parts

Once you have disassembled the chamber, thoroughly clean each individual part using the following steps:

- Rinse all removable parts, such as the boiling chamber, lid, and any other components, with warm water to remove any loose debris.

- Prepare a mixture of mild dish soap and warm water in a basin or bucket.

- Submerge each part in the soapy water and use a soft brush or cloth to gently scrub away any stains, mineral deposits, or buildup.

- Pay close attention to hard-to-reach areas, such as corners and crevices, ensuring they are thoroughly cleaned and free from any residue.

- Rinse each part again in clean water to remove any soap residue.

- For stubborn stains or mineral deposits, you may use an appropriate descaling solution or vinegar to help dissolve them. Follow the manufacturer’s instructions and rinse thoroughly afterward.

Reassembling The Chamber

After cleaning each individual part, it’s time to reassemble the distiller boiling chamber:

- Refer to your distiller’s user manual or documentation to ensure that each part is correctly aligned and placed in its designated position.

- Carefully fit the cleaned boiling chamber back onto the base unit, ensuring a secure and proper seal.

- Use the screws or clips that were removed earlier to fasten the chamber back in place. Tighten them appropriately, but avoid overtightening to prevent damage.

- Double-check that all connections are secure and that the lid fits snugly onto the boiling chamber.

- Plug in the distiller and perform a test run to ensure everything is functioning correctly.

By following these additional steps for deep cleaning and intensive maintenance, you can effectively clean your distiller boiling chamber and keep it in optimal condition. Remember to regularly inspect and clean your distiller to prevent the buildup of mineral deposits and ensure the production of clean and pure distilled water.

Ensuring Safety And Longevity Of The Distiller

To ensure the safety and longevity of your distiller, it is important to properly clean the boiling chamber. Regular maintenance and thorough cleaning will remove any built-up residue and prevent any potential health risks, allowing your distiller to perform at its best and last for years to come.

Regular Maintenance Routine

To ensure the safety and longevity of your distiller, it is crucial to establish a regular maintenance routine. Here are some key steps to follow:

Inspect and clean the boiling chamber regularly: Remove any residue or buildup from the boiling chamber of your distiller. This helps to prevent clogs and maintains efficient operation. Use a non-abrasive cleaner and a soft cloth to wipe the inside of the chamber.

Check and replace filters: Depending on the type of distiller you have, it may be equipped with different types of filters. Regularly inspect these filters and replace them as needed. Clean filters ensure the purity of the distilled water and prevent any contaminants from entering the boiling chamber.

Descale the distiller: Over time, mineral deposits can build up inside the boiling chamber. This can affect the performance of the distiller and reduce its lifespan. Follow the manufacturer’s instructions to descale the distiller using a descaling solution or a vinegar-water mixture.

Check and clean the condenser: The condenser is responsible for cooling the steam from the boiling chamber and converting it back into liquid form. Inspect the condenser regularly and clean it to remove any debris or buildup. This helps maintain efficient cooling and prevents any blockages.

Replace any worn-out parts: Keep an eye on the various components of your distiller and replace any parts that show signs of wear and tear. This includes seals, gaskets, and other moving parts. Regularly check the manufacturer’s website or contact their customer support for information on replacement parts.

Professional Servicing Options

While regular maintenance can significantly extend the life of your distiller, there may come a time when professional servicing is necessary. Here are some options to consider:

Manufacturer’s service center: Most distiller manufacturers have their own authorized service centers. These centers specialize in repairing and servicing their specific brand of distillers. Check the manufacturer’s website or reach out to their customer support for information on service centers near you.

Certified technicians: If you cannot access a manufacturer’s service center, look for certified technicians experienced in distiller repair and servicing. They usually have the knowledge and expertise to handle various brands and types of distillers. Check online directories or ask for recommendations from friends or local appliance stores.

Extended warranty coverage: If your distiller is still under warranty, contact the warranty provider to inquire about servicing options. Some extended warranty plans include coverage for servicing or repairs, which can save you money on professional assistance.

Online resources: Many distiller manufacturers provide troubleshooting guides and video tutorials on their websites. These resources can help you identify common issues and guide you through the necessary steps to rectify them. However, it’s important to note that self-servicing may void the warranty, so exercise caution.

By following a regular maintenance routine and considering professional servicing options when needed, you can ensure the safety and longevity of your distiller. Taking care of your distiller not only maximizes its performance but also helps in obtaining clean and pure distilled water for your everyday needs.

Remember to always refer to the manufacturer’s instructions for specific maintenance requirements and guidelines.

Frequently Asked Questions For How To Clean The Distiller Boiling Chamber

How Often Should The Distiller Boiling Chamber Be Cleaned?

It is recommended to clean the distiller boiling chamber every two to three months to ensure optimal functionality and prevent buildup of mineral deposits and impurities.

What Supplies Are Needed To Clean The Distiller Boiling Chamber?

To clean the distiller boiling chamber, you will need white vinegar, water, a soft cloth or sponge, and a small brush to scrub away any stubborn residue.

Can I Use Bleach To Clean The Distiller Boiling Chamber?

No, it is not recommended to use bleach to clean the distiller boiling chamber as it can leave behind harmful residues that can affect the quality of distilled water and potentially damage the appliance.

How Do I Clean The Heating Element In The Distiller Boiling Chamber?

To clean the heating element, mix equal parts white vinegar and water in a bowl, then soak a cloth or sponge in the mixture and gently scrub the heating element to remove any mineral deposits or residue.

Conclusion

Maintaining a clean distiller boiling chamber is essential for ensuring the purity of your distilled water. By following the steps outlined in this blog post, you can easily remove mineral deposits and residues that accumulate over time. Regular cleaning will not only enhance the efficiency of your distiller but also prolong its lifespan.

Start by unplugging the distiller and allowing it to cool down before emptying the boiling chamber. Use a non-abrasive cleaner and a soft cloth to gently scrub away any deposits. Rinse thoroughly to remove any cleaning solution residue. Remember to also clean the exterior of the distiller and the condensation coil.

By taking the time to clean your distiller, you can enjoy the benefits of pure and safe water for years to come.

As an Amazon Associate, Cleanestor earns from qualifying purchases at no additional cost to you.