To clean a crankshaft position sensor, disconnect it from the vehicle’s electrical system and use a sensor-safe cleaner to remove any dirt or debris.

The crankshaft position sensor is a crucial component in a vehicle’s engine system. It provides vital information about the position and speed of the crankshaft, allowing the engine control unit to make necessary adjustments for proper ignition timing and fuel injection.

Over time, the sensor can become dirty or contaminated, which can lead to inaccurate readings and performance issues. Cleaning the sensor regularly helps ensure its proper functioning and can prevent costly repairs. We will discuss the steps to clean a crankshaft position sensor effectively.

Following these steps will help keep your engine running smoothly and efficiently.

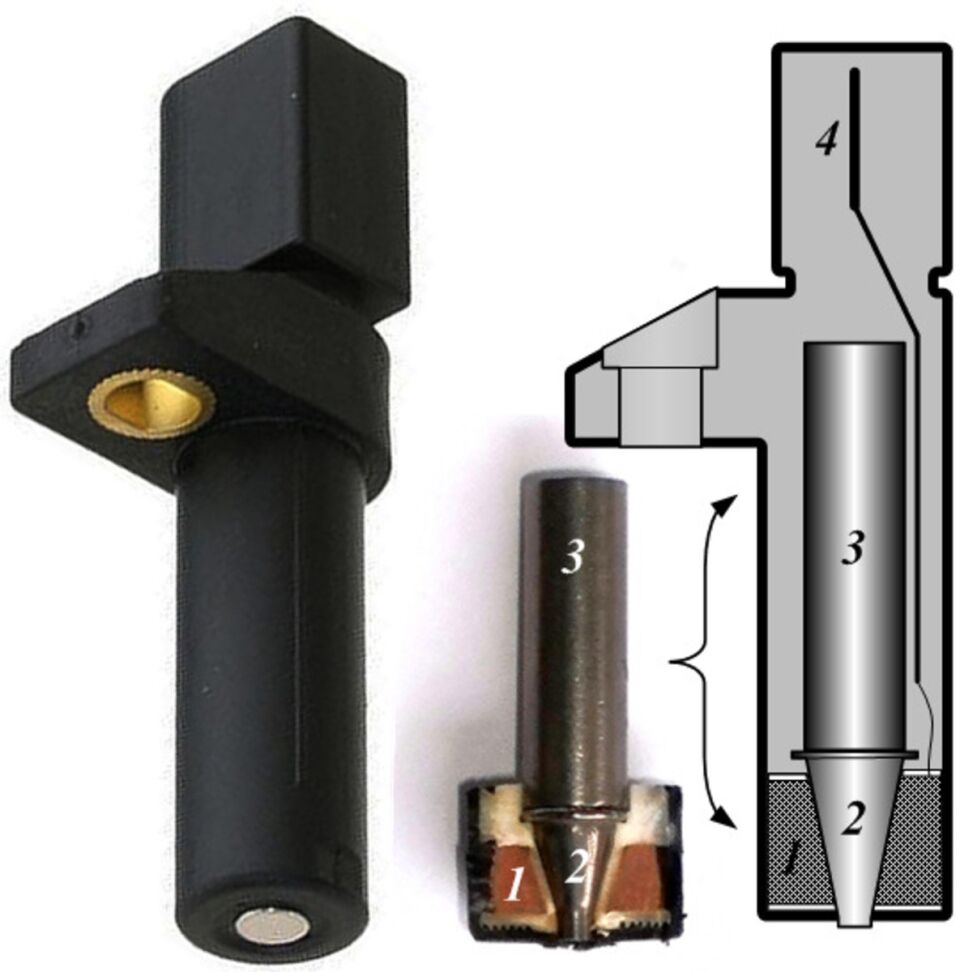

Credit: axleaddict.com

Understanding The Importance Of A Clean Crankshaft Position Sensor

The crankshaft position sensor plays a crucial role in the overall performance of an engine. This small but mighty sensor is responsible for providing the engine control unit (ecu) with vital data about the position and rotational speed of the crankshaft.

By keeping this sensor clean, you can ensure accurate readings and optimal engine performance. In this section, we will explore the role of the crankshaft position sensor in engine performance and the effects of a dirty sensor.

Role Of The Crankshaft Position Sensor In Engine Performance

The crankshaft position sensor serves as the eyes and ears of the engine, providing vital information to the ecu. Here’s a closer look at its role:

- Detection of crankshaft position: The sensor detects the precise position of the crankshaft at any given moment, allowing the ecu to determine the firing order of the engine cylinders.

- Timing accuracy: By accurately tracking the crankshaft’s rotational speed, the sensor ensures proper timing of the engine’s fuel injection and ignition systems. This helps maintain the overall efficiency and power output of the engine.

- Optimal fuel consumption: With the data provided by the crankshaft position sensor, the ecu can precisely regulate the amount and timing of fuel injection, promoting fuel efficiency and reducing emissions.

- Engine smoothness: For smooth and balanced engine operation, the ecu relies on the crankshaft position sensor to monitor the engine’s rotational speed and detect any variations or irregularities. This enables the ecu to make necessary adjustments to maintain engine performance.

Effects Of A Dirty Crankshaft Position Sensor

A dirty crankshaft position sensor can have detrimental effects on engine performance and overall vehicle operation. Here are some of the potential consequences:

- Inaccurate timing: A dirty or contaminated sensor may provide incorrect readings, leading to improper timing of the fuel injection and ignition systems. This can result in misfires, engine hesitation, and poor acceleration.

- Reduced fuel efficiency: Since a dirty crankshaft position sensor can provide flawed data to the ecu, the fuel injection system may operate inefficiently. This can lead to excessive fuel consumption and decreased gas mileage.

- Rough idling: The ecu relies on accurate data from the crankshaft position sensor to maintain a steady idle speed. If the sensor is dirty, it may provide inconsistent readings, resulting in engine roughness or stalling when idling.

- Increased emissions: When the timing and fuel injection are not properly regulated due to a dirty sensor, the engine may produce higher levels of harmful emissions. This can lead to a failed emissions test and contribute to environmental pollution.

- Engine malfunction: In extreme cases, a severely dirty or malfunctioning crankshaft position sensor can cause the engine to fail to start or stall during operation. This can leave you stranded and in need of costly repairs.

Regularly cleaning the crankshaft position sensor is essential to maintain its accuracy and ensure optimal engine performance. By understanding the crucial role it plays and the potential consequences of neglecting its cleanliness, you can take the necessary steps to keep your sensor in top shape and enjoy a smooth-running engine.

Identifying The Signs Of A Dirty Crankshaft Position Sensor

The crankshaft position sensor is a crucial component of your vehicle’s engine management system. It helps to identify the rotational position of the crankshaft, which is essential for proper ignition timing and fuel injection. Over time, the sensor can get dirty and affect its performance.

In this section, we will explore the common symptoms of a dirty crankshaft position sensor and diagnostic methods to identify sensor issues.

Common Symptoms Of A Dirty Sensor

- Engine stalling or intermittent starting issues: A dirty crankshaft position sensor can cause the engine to stall or struggle to start. This can happen when the sensor fails to provide accurate information about the crankshaft’s position to the engine control unit (ecu).

- Rough or inconsistent idling: If the crankshaft position sensor is dirty, it may not accurately monitor the crankshaft’s rotational speed. As a result, the ecu may receive incorrect information, leading to rough idling or inconsistent engine performance.

- Engine misfires: A dirty crankshaft position sensor affects the ignition timing, which can result in engine misfires. This can cause decreased power, reduced fuel efficiency, and even damage to the catalytic converter over time.

- Reduced engine power: When a dirty sensor provides inaccurate data, the ecu may struggle to determine the appropriate fuel and ignition timing, resulting in reduced engine power.

Diagnostic Methods For Identifying Sensor Issues

- Scanning for trouble codes: Using an obd-ii scanner, you can check for any trouble codes related to the crankshaft position sensor. These codes can provide valuable information about potential sensor issues.

- Visual inspection: Sometimes, debris or grime can accumulate on the sensor, affecting its performance. Conduct a visual inspection to ensure that the sensor is clean and free from any dirt or oil buildup.

- Testing the sensor’s electrical connections: Faulty or loose electrical connections can also lead to sensor issues. Check the sensor’s wiring and connectors to ensure they are properly connected and in good condition.

- Using a multimeter: A multimeter can be used to measure the resistance and voltage output of the crankshaft position sensor. Comparing the readings to the manufacturer’s specifications can help determine if the sensor is working correctly.

- Testing sensor output: Some advanced diagnostic tools allow you to monitor the sensor’s output while the engine is running. By comparing the actual readings to the expected values, you can identify any irregularities in the sensor’s performance.

It’s essential to identify the signs of a dirty crankshaft position sensor early on to prevent further damage to your vehicle’s engine. Understanding the common symptoms and utilizing diagnostic methods can help you address any sensor issues promptly and ensure optimal engine performance.

Preparing For The Cleaning Process

Gathering The Required Tools And Equipment

To effectively clean the crankshaft position sensor, it’s essential to have the right tools and equipment ready. Here are the items you’ll need:

- Flathead screwdriver: This tool will help you remove any screws or clips holding the sensor in place.

- Cleaning solution: Choose a non-abrasive cleaner specifically designed for electronic components.

- Cotton swabs or soft-bristle brush: These provide a gentle yet thorough cleaning method.

- Compressed air canister: Use this to blow away any debris that may be caught in the sensor.

- Safety goggles and gloves: Protect your eyes and hands while working on the sensor.

- Shop rags or lint-free cloths: Ideal for drying the sensor after cleaning.

- Diagnostic tool (optional): If you have access to a diagnostic tool, it can help pinpoint any issues with the sensor.

Make sure you gather all these tools and have them readily available before starting the cleaning process.

Taking Safety Precautions

It’s important to prioritize safety when cleaning the crankshaft position sensor to prevent any accidents or damage. Here are some safety precautions to keep in mind:

- Disconnect the battery: Before working on any electrical component, always disconnect the battery to prevent electric shock and other issues.

- Work in a well-ventilated area: Cleaning agents can emit fumes, so choose a workspace that is properly ventilated. This will help prevent inhalation of potentially harmful chemicals.

- Wear safety goggles and gloves: Protect your eyes from splashes and your hands from any chemical residues.

- Allow the engine to cool: Make sure the engine is completely cool to the touch before attempting to clean the sensor. Hot engine components can cause burns.

- Follow proper handling procedures: Be mindful of the fragile nature of the sensor and handle it with care. Avoid applying excessive force or dropping it.

By following these safety precautions, you can ensure a safe environment and minimize the risk of accidents or damage to the sensor.

Remember to always exercise caution and follow any additional safety guidelines provided by the vehicle’s manufacturer or service manual.

Step 1: Locating The Crankshaft Position Sensor

If you’re experiencing issues with your car’s engine, specifically the ignition system, chances are it’s related to the crankshaft position sensor. In this step, we’ll guide you on how to locate this important sensor in different car models. Keep in mind that the position may vary depending on the manufacturer and model of your vehicle.

Identifying The Sensor’s Position In Different Car Models

In order to clean the crankshaft position sensor, you first need to locate it. Here’s a breakdown of where you can find the sensor in various car models:

Honda civic:

- The crankshaft position sensor in the honda civic is typically situated near the crankshaft pulley.

- It can be found on the passenger side of the engine, closer to the bottom.

Ford focus:

- For the ford focus, you’ll find the crankshaft position sensor near the camshaft position sensor.

- It’s often located on the front side of the engine block, near the bottom.

Toyota camry:

- In the toyota camry, the crankshaft position sensor is usually positioned behind the timing belt.

- You may need to remove the timing belt cover to access the sensor.

Chevrolet silverado:

- When it comes to the chevrolet silverado, the crankshaft position sensor is generally located on the front side of the engine block.

- Look for it near the bottom, close to the crankshaft pulley.

Removing Obstacles To Access The Sensor

Before you can start cleaning the crankshaft position sensor, you might encounter some obstacles that impede your access. Here are a few common obstacles and ways to overcome them:

Engine covers:

- Some car models come with engine covers that need to be removed to access the crankshaft position sensor.

- Locate the screws or bolts securing the cover and use the appropriate tools to remove them.

Components obstructing the sensor:

- In certain cases, other components such as belts, pulleys, or hoses may obstruct your reach to the sensor.

- Carefully detach or move these components out of the way to gain clear access to the sensor.

Limited workspace:

- Working in tight spaces can be challenging. Ensure you have the necessary tools and consider using a flashlight to illuminate the area.

- If needed, partially disassemble adjacent engine parts to create more workspace.

Now that you know how to locate the crankshaft position sensor in different car models and how to overcome obstacles hindering its access, you’re ready to proceed with cleaning it thoroughly. Stay tuned for our next steps to successfully clean the crankshaft position sensor.

Step 2: Removing The Crankshaft Position Sensor

To clean the crankshaft position sensor, begin by following step 2: removing the sensor. This process is crucial in maintaining the sensor’s cleanliness and ensuring accurate readings for your vehicle’s performance.

Properly Disconnecting The Sensor Wiring

To begin the process of removing the crankshaft position sensor, it’s crucial to properly disconnect the sensor wiring. This ensures that you can safely detach the sensor from the engine block without causing any damage. Follow these steps to disconnect the sensor wiring:

- Locate the electrical connector attached to the crankshaft position sensor.

- Gently grasp the connector and wiggle it back and forth to loosen any dirt or debris that may have accumulated.

- Once loosened, press the locking tab or lever on the connector, usually located on the side or top, to release it.

- Carefully pull the connector away from the sensor, making sure not to force it or yank on the wires.

- Inspect the connector for any signs of damage or corrosion. If found, it may be necessary to replace the connector before reinstallation.

Safely Detaching The Sensor From The Engine Block

After disconnecting the sensor wiring, you can proceed to safely detach the crankshaft position sensor from the engine block. Follow these steps to ensure a smooth removal process:

- Locate the sensor, typically mounted on the engine block, near the crankshaft pulley or flywheel.

- Use a wrench or socket set compatible with the sensor’s mounting bolt or screws.

- Carefully loosen the fasteners holding the sensor in place, turning counterclockwise to remove them.

- Once the fasteners are fully loosened, gently pull the sensor out of its position.

- Be cautious not to damage the sensor or any surrounding components, as they may be delicate.

- Inspect the sensor and its mounting area for any signs of debris, oil, or damage. Clean or address any issues accordingly before reinstallation.

Now that you have successfully removed the crankshaft position sensor, you can proceed with further maintenance or replacement tasks. Remember to follow the manufacturer’s instructions or consult a professional mechanic for guidance if needed.

Note: the next section of this blog post will cover the cleaning process for the crankshaft position sensor. Stay tuned for step 3: cleaning the sensor.

Step 3: Cleaning The Crankshaft Position Sensor

Before you start cleaning the crankshaft position sensor, it is essential to choose the right cleaning solution. Using a soft brush or cloth, you can then remove any dirt and debris. It is important to ensure a thorough cleaning without damaging the sensor.

Choosing The Right Cleaning Solution

- Isopropyl alcohol: This is a commonly used cleaning solution for electronic components as it evaporates quickly and leaves no residue.

- Electrical contact cleaner: Specifically designed for cleaning electrical components, this solution effectively removes dirt and grime.

- Maf sensor cleaner: This specialized cleaner is gentle and safe to use on sensitive sensors.

Using A Soft Brush Or Cloth To Remove Dirt And Debris

- Gently brush away loose dirt: Using a soft-bristle brush, carefully remove any loose dirt or debris from the crankshaft position sensor.

- Use a microfiber cloth: For stubborn dirt or grime, lightly dampen a microfiber cloth with your chosen cleaning solution and gently wipe the sensor.

Ensuring A Thorough Cleaning Without Damaging The Sensor

- Avoid using excessive force: When cleaning the sensor, be gentle to avoid causing damage. Apply light pressure to remove dirt without applying too much force.

- Do not immerse the sensor in cleaning solution: Only use the cleaning solution on the cloth or brush and avoid submerging the sensor itself.

- Allow the sensor to dry completely: Once you have cleaned the sensor, ensure it dries thoroughly before reconnecting it. This will prevent any moisture from causing issues with the sensor’s functionality.

Remember to exercise caution and follow the manufacturer’s instructions when cleaning the crankshaft position sensor. Taking these precautions will help ensure an effective and damage-free cleaning process.

Step 4: Drying And Inspecting The Sensor

Step 4 involves drying and inspecting the crankshaft position sensor after cleaning. This essential step ensures proper functioning and helps prevent future issues.

Allowing Sufficient Time For The Sensor To Dry

After cleaning the crankshaft position sensor, it is crucial to allow sufficient time for it to dry properly. This will ensure that no moisture remains, which could interfere with its functionality. To effectively dry the sensor, follow these steps:

- Gently pat the sensor with a clean, lint-free cloth to remove excess moisture.

- Leave the sensor in a well-ventilated area or use compressed air to blow away any remaining moisture.

- Avoid using heat sources, such as hairdryers or heaters, as they can damage the sensor.

Conducting A Visual Inspection For Any Remaining Dirt Or Damage

Once the sensor is dry, it is important to visually inspect it for any remaining dirt or damage. This step is crucial to ensure that the sensor is in optimal condition. Here are the steps to follow when conducting a visual inspection:

- Carefully examine the sensor for any signs of dirt, debris, or residue that may have been missed during the cleaning process.

- Check for any physical damage such as cracks, dents, or corrosion on the sensor.

- Ensure that the electrical connectors and wiring attached to the sensor are intact and undamaged.

By conducting a thorough visual inspection, you can identify any potential issues that may affect the performance of the crankshaft position sensor. If you notice any remaining dirt or damage, repeat the cleaning process or consider replacing the sensor if necessary.

Remember, taking the time to dry and inspect the sensor properly will contribute to the smooth operation of your vehicle’s engine and ensure accurate readings from the crankshaft position sensor.

Step 5: Reinstalling The Crankshaft Position Sensor

Ensuring Proper Alignment And Connection Of The Sensor

To reinstall the crankshaft position sensor correctly, you need to ensure proper alignment and connection. Here are the steps to follow:

- Align the sensor: Make sure the sensor is properly aligned with the mounting hole on the engine block. Take your time to ensure it is in the correct position before proceeding.

- Insert the sensor: Gently insert the sensor into the mounting hole, being careful not to force it. A snug fit is desired, but avoid applying excessive pressure.

- Secure the sensor: Once the sensor is inserted, secure it using the retaining bolt or clip provided. Ensure the sensor is firmly held in place to prevent any movement during operation.

- Connect the electrical connector: Reconnect the electrical connector to the sensor. Make sure the connection is secure and properly seated. Give it a gentle tug to confirm it is attached firmly.

- Double-check the alignment: After connecting the electrical connector, verify that the sensor is still properly aligned. If necessary, make any adjustments needed to achieve the correct position.

Securely Fastening The Sensor To The Engine Block

To complete the reinstallation process, it is crucial to securely fasten the crankshaft position sensor to the engine block. Follow these steps:

- Tighten the retaining bolt or clip: Using the appropriate tool, tighten the retaining bolt or clip that secures the sensor to the engine block. Be careful not to overtighten, as it may damage the sensor or the mounting hole.

- Check for proper fit: Ensure that the sensor is securely fastened and there is no movement or play. A loose sensor can lead to inaccurate readings and potential engine issues.

- Conduct a final inspection: Before moving on to the next steps, visually inspect the sensor to verify that it is properly installed and securely fastened. Check for any signs of damage or misalignment.

- Reassemble other components: If you had to remove any other components during the process, reattach them now. Make sure everything is properly reassembled and any fasteners are securely tightened.

- Test the sensor: Once everything is reinstalled, start the engine and monitor the crankshaft position sensor’s performance. If the engine runs smoothly and there are no error codes related to the sensor, your reinstallation was successful.

By following these steps, you can ensure that the crankshaft position sensor is properly aligned, connected, and securely fastened to the engine block. This will help maintain accurate readings and prevent any potential issues down the road.

Testing The Sensor’s Functionality

To ensure the smooth functioning of your vehicle, it is crucial to regularly test the functionality of the crankshaft position sensor. Cleaning the sensor is an effective way to maintain its accuracy and performance, helping to prevent potential issues and ensuring optimal engine performance. Here are the details:

Starting The Engine And Checking For Proper Functioning

- Start the engine and let it run for a few minutes to warm up.

- Observe the sensor for any visible signs of damage such as cracks or corrosion.

- Check the wiring connections for any loose or frayed wires.

- Use a multimeter to measure the voltage output of the sensor. It should be within the specified range.

- Test the sensor’s resistance by connecting the multimeter probes to the appropriate terminals. The resistance value should fall within the specified range.

- Inspect the sensor for any debris or dirt that may be obstructing its proper functioning.

- If any issues are identified during these tests, consider replacing the sensor.

Conducting A Test Drive To Verify Improved Performance

- Take the vehicle for a test drive, making note of any unusual engine behavior.

- Pay attention to the engine’s acceleration, smoothness, and responsiveness.

- Monitor the vehicle’s rpms while accelerating and decelerating.

- Observe if there are any sudden drops or fluctuations in the rpms.

- Note down any symptoms such as stalling, misfires, or difficulty starting the engine.

- Compare the vehicle’s performance to its previous state before cleaning the sensor.

- If the sensor cleaning was effective, you should experience improved engine performance and fewer related issues.

Remember, regular maintenance and cleaning of the crankshaft position sensor can greatly enhance the overall performance of your vehicle’s engine. By following these steps, you can test the sensor’s functionality and ensure that it is working properly. Conducting a test drive after cleaning the sensor will provide valuable insights into any improvements in the engine’s performance.

Maintenance Tips For A Clean Crankshaft Position Sensor

Keep your crankshaft position sensor clean with these maintenance tips. Regularly remove dirt and debris, use electrical contact cleaner, and avoid excessive force when cleaning.

Regular Cleaning Schedule For Optimal Performance

Regular cleaning of the crankshaft position sensor is essential to ensure its optimal performance. By following a cleaning schedule, you can prevent dirt buildup and keep the sensor in good working condition. Here are some guidelines to help you maintain a clean crankshaft position sensor:

- Clean the sensor at least once every six months to remove any accumulated dirt or debris. This will help prevent performance issues and keep the sensor functioning properly.

- Begin by disconnecting the sensor from the wiring harness. This will make it easier to access and clean the sensor without causing any damage.

- Use a soft brush or compressed air to gently remove any loose dirt or debris from the sensor. Be careful not to apply too much pressure, as this could cause damage to the sensor.

- Once the loose dirt is removed, you can use an electronic cleaner or contact cleaner to clean the sensor more thoroughly. Spray the cleaner onto a clean cloth and gently wipe the sensor, making sure to remove any grime or buildup.

- After cleaning the sensor, allow it to dry completely before reinstallation. Moisture can cause damage to the sensor, so it’s important to ensure it is completely dry before reconnecting it.

- Before reinstalling the sensor, inspect the wiring harness for any damage or wear. If you notice any issues, they should be addressed before reconnecting the sensor.

- Once the sensor is dry and the wiring harness is in good condition, you can reconnect the sensor and secure it properly.

Preventive Measures To Minimize Dirt Accumulation

In addition to regular cleaning, there are preventive measures you can take to minimize dirt accumulation on the crankshaft position sensor. By implementing these measures, you can help to prolong the sensor’s lifespan and reduce the need for frequent cleanings. Here are some preventive tips to consider:

- Keep the surrounding area clean: Ensure that the engine bay is free of debris, dust, and dirt. Regularly clean the engine bay and remove any foreign objects that may find their way to the sensor.

- Use a protective cover: Consider using a protective cover or shield for the crankshaft position sensor. This can help to prevent direct exposure to dirt and debris, reducing the likelihood of buildup.

- Avoid harsh environments: Limit the exposure of the sensor to harsh environments that may contain excessive dirt, dust, or moisture. Shielding the sensor from such conditions can minimize the risk of dirt accumulation.

- Inspect and maintain other engine components: Regularly inspect and maintain other engine components, such as the air filter and pcv system. Keeping these components in good condition can help prevent dirt and debris from reaching the sensor.

- Check for oil leaks: Oil leaks can attract dirt and debris, increasing the likelihood of buildup on the sensor. Regularly inspect for oil leaks and address any issues promptly.

By following these preventive measures and adhering to a regular cleaning schedule, you can ensure a clean crankshaft position sensor and optimal performance of your vehicle. Regular maintenance and care will help to extend the lifespan of the sensor and minimize the risk of performance issues.

Frequently Asked Questions On How To Clean Crankshaft Position Sensor

How Do You Clean A Crankshaft Position Sensor?

To clean a crankshaft position sensor, first locate the sensor on the engine. Disconnect the electrical connector and remove any mounting bolts holding the sensor in place. Use a sensor-safe cleaner to gently clean the sensor’s tip and surrounding area. Allow it to air dry before reinstalling the sensor.

What Are The Signs Of A Dirty Crankshaft Position Sensor?

Dirty or faulty crankshaft position sensor can cause problems such as engine misfires, stalling, and poor acceleration. You may also experience issues with starting your vehicle, rough idling, or a decrease in fuel efficiency. If you notice any of these symptoms, it may be time to clean or replace the crankshaft position sensor.

Can A Dirty Crankshaft Position Sensor Cause A Check Engine Light?

Yes, a dirty or faulty crankshaft position sensor can trigger the check engine light. The sensor plays a crucial role in the engine’s ignition timing and fuel delivery. If it is dirty or malfunctioning, the engine control unit may receive incorrect information and result in the check engine light being illuminated. Cleaning or replacing the sensor can often resolve this issue.

Conclusion

Cleaning the crankshaft position sensor is an essential task that can help maintain the performance and efficiency of your vehicle. By following the steps mentioned in this blog post, you can effectively remove any dirt or debris that may have accumulated on the sensor.

Regularly cleaning the sensor can prevent issues such as rough idling, engine misfires, and stalling. Remember to use the right tools and take precautions to avoid damaging the sensor during the cleaning process. It is recommended to consult your vehicle’s manual or seek professional assistance if you are unsure about the cleaning procedure.

Keeping your crankshaft position sensor clean can contribute to the overall health of your engine and ensure smooth operation. So, don’t delay, give your sensor the attention it deserves, and enjoy a trouble-free driving experience.

As an Amazon Associate, Cleanestor earns from qualifying purchases at no additional cost to you.