To clean aluminum engine parts, use vinegar or a mixture of mild detergent and water. These options are effective in removing dirt and grime from aluminum surfaces without causing damage. Additionally, borax is another alternative that can be found in the laundry aisle of a supermarket.

Cleaning oxidation off aluminum can be done using various methods, including scrubbing with a soft brush and a mixture of vinegar and water, or using commercial aluminum cleaners specifically designed for oxidation removal.

It is important to follow the instructions provided by the manufacturer of the cleaning product and to rinse the aluminum thoroughly after cleaning to avoid any surface damage. Regular cleaning and maintenance of aluminum engine parts will help to prolong their lifespan and maintain their functionality.

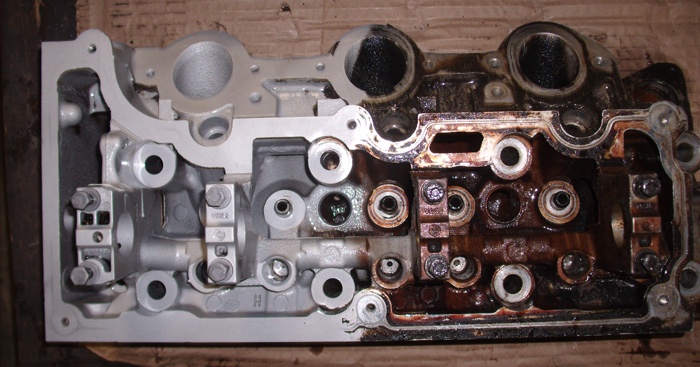

Credit: www.enginebuildermag.com

Importance Of Cleaning Aluminum Engine Parts

Cleaning aluminum engine parts is a crucial maintenance task that should not be overlooked. It offers several benefits that can significantly improve the performance and lifespan of your engine. Let’s explore these benefits in detail:

Extends Engine Lifespan

- Regularly cleaning aluminum engine parts removes built-up dirt, grime, and debris that can potentially clog or restrict the flow of oil or coolant.

- By keeping the engine components clean, you ensure that they can function optimally without any obstruction. This helps in preventing premature wear and tear of the engine.

- Cleaning extends the lifespan of aluminum engine parts by reducing the risk of overheating, which can cause severe damage to the engine.

Improves Engine Performance

- Clean aluminum engine parts allow for better heat transfer and dissipation, which is crucial for maintaining optimal engine temperature.

- Improved heat management helps the engine to run more efficiently and minimizes the risk of overheating.

- Cleaning also ensures that all the engine components work together smoothly, promoting better overall performance.

Prevents Corrosion

- Aluminum engine parts are susceptible to corrosion, especially when exposed to moisture and other corrosive elements.

- Regular cleaning removes corrosive substances and protects the aluminum surface from further damage.

- A clean engine reduces the risk of rust formation, which can lead to leaks or cracks in the engine components.

Cleaning aluminum engine parts is vital for extending the engine’s lifespan, improving its performance, and preventing corrosion. By incorporating regular cleaning into your engine maintenance routine, you can keep your engine running smoothly and efficiently for a longer period.

Choosing The Right Cleaner For Aluminum Engine Parts

Cleaning aluminum engine parts require the use of the right cleaner to ensure effective yet safe results. When selecting a cleaner, there are several factors to consider, such as compatibility with aluminum, non-acidic and non-abrasive properties, and the product’s label instructions.

To help you make an informed decision, here are some key points to keep in mind:

Consider types of cleaners available:

- Degreasers: These cleaners are specifically designed to remove grease and grime from engine parts. They are effective in breaking down tough deposits but may not be suitable for all types of aluminum.

- Aluminum cleaners: These cleaners are formulated to clean and brighten aluminum surfaces without causing damage. They are gentle yet effective in removing oxidation and stains from engine parts.

Read product labels for compatibility with aluminum:

- Before using any cleaner on your aluminum engine parts, thoroughly read the product label to ensure it is safe to use on aluminum surfaces. Some cleaners may contain ingredients that can corrode or discolor aluminum.

- Look for cleaners that specifically state they are safe for use on aluminum surfaces. This will help prevent any unwanted damage or discoloration.

Look for non-acidic and non-abrasive cleaners:

- Acidic cleaners can etch the surface of aluminum, causing irreversible damage. Therefore, it is crucial to choose a cleaner that is non-acidic to protect the integrity of your engine parts.

- Similarly, abrasive cleaners can scratch or dull the surface of aluminum, compromising its appearance and functionality. Opt for non-abrasive cleaners to preserve the smoothness and shine of your aluminum engine parts.

By considering these factors and selecting the right cleaner for your aluminum engine parts, you can effectively clean and maintain their appearance without causing any damage. Remember to always follow the product instructions for best results and ensure the longevity of your engine parts.

Step-By-Step Guide To Cleaning Aluminum Engine Parts

Discover the step-by-step guide to effectively clean your aluminum engine parts. Learn the best techniques and tools to remove dirt and oxidation, leaving your parts looking shiny and like new.

Preparation

Gather necessary tools and materials: Before starting the cleaning process, make sure you have the following items on hand:

- Soft-bristle brush or sponge

- Mild detergent

- Water hose or bucket of water

- Clean cloth or towel

Disconnect the battery and remove any sensitive components: To avoid any damage, disconnect the battery and remove any sensitive components such as spark plugs or sensors before cleaning the aluminum engine parts.

Cleaning Process

- Rinse off loose dirt and debris with water: Start by rinsing off the loose dirt and debris from the aluminum parts using a water hose or bucket of water. This will help remove any surface dirt and make the cleaning process easier.

- Apply the cleaner to the aluminum parts: Apply a mild detergent or an aluminum cleaner to the surface of the aluminum parts. Make sure to follow the instructions on the cleaner’s label for the best results.

- Use a soft-bristle brush or sponge to scrub the surface: Gently scrub the surface of the aluminum parts using a soft-bristle brush or sponge. This will help remove any stubborn stains or grime from the surface. Avoid using abrasive tools or cleaners as they can cause damage to the aluminum.

- Rinse the parts thoroughly with water: Once you have scrubbed the surface, thoroughly rinse the aluminum parts with clean water. Make sure to remove all traces of the cleaner from the surface.

- Dry the parts completely before reassembling: After rinsing, use a clean cloth or towel to dry the aluminum parts completely. This will prevent any water spots or corrosion from forming. Make sure the parts are completely dry before reassembling them.

Additional Tips

Use a mild detergent for stubborn stains: If you encounter stubborn stains or grime on the aluminum parts, use a mild detergent specifically designed for aluminum cleaning. This will help break down the stains without causing damage to the surface.

- Avoid using abrasive tools or cleaners: When cleaning aluminum engine parts, it’s important to avoid using abrasive tools or cleaners as they can cause scratches or damage to the aluminum surface. Stick to soft-bristle brushes or sponges to avoid any potential harm.

- Take precautions to prevent water damage: Since aluminum is a metal prone to corrosion, it’s essential to take precautions to prevent water damage. Make sure to dry the parts thoroughly before reassembling them to avoid any moisture buildup.

By following these step-by-step instructions and additional tips, you can effectively clean your aluminum engine parts and keep them in optimal condition. Remember to gather the necessary tools, disconnect sensitive components, rinse off loose dirt, apply the cleaner, scrub gently, rinse thoroughly, and dry completely before reassembling.

Additionally, using a mild detergent, avoiding abrasive tools or cleaners, and taking precautions against water damage will ensure a successful cleaning process.

Maintaining Aluminum Engine Parts

To clean aluminum engine parts, start by using a mild detergent and water mixture or vinegar as an effective cleaning resource. You can also use borax, found in the laundry aisle, as an alternative cleaner.

Regular inspection and cleaning:

- Perform regular visual inspections of your aluminum engine parts to identify any build-up of dirt, grease, or other contaminants.

- Use a soft bristle brush or a cloth to gently remove any loose debris from the surface of the parts.

- In areas that are difficult to reach, such as crevices or intricate designs, use compressed air to blow away any dirt or dust.

- Inspect the parts carefully for any signs of corrosion or damage. If you notice any issues, take immediate action to prevent further damage.

- It is essential to clean your aluminum parts regularly to prevent the accumulation of dirt, grease, or contaminants that can lead to corrosion or performance issues.

Applying protective coatings or sealants:

- After cleaning, consider applying a protective coating or sealant to your aluminum engine parts. These protectants can help prevent corrosion and extend the lifespan of your parts.

- Choose a coating or sealant specifically designed for aluminum surfaces. Follow the manufacturer’s instructions for application, ensuring even coverage.

- Protective coatings can come in various forms, such as sprays, waxes, or ceramic coatings. Select the product that best suits your needs and preferences.

- Apply the coating or sealant in a well-ventilated area, following all safety precautions mentioned on the product label.

- Regularly check the condition of the protective coating and reapply as needed, especially if your engine parts are exposed to harsh environmental conditions.

Checking for signs of corrosion or damage:

- Inspect your aluminum engine parts for signs of corrosion, such as white oxidation or pitting. Corrosion can compromise the integrity and performance of your parts.

- If you notice any corrosion, address it promptly. Use a specialized aluminum cleaner or a mixture of water and mild detergent to remove the oxidation.

- Be cautious not to use abrasive materials or harsh chemicals that can damage the aluminum surface.

- Pay close attention to areas where different metals come into contact with the aluminum parts, as this can accelerate corrosion.

- Regularly assess your aluminum parts for any signs of damage, such as cracks, dents, or leaks. Address these issues immediately to prevent further deterioration and potential engine failure.

By following these maintenance practices, you can ensure that your aluminum engine parts remain clean, protected, and in optimal condition for enhanced performance and longevity.

What Is The Best Cleaner For Aluminum Parts?

The best cleaner for aluminum parts is vinegar, which is an effective resource for cleaning aluminum. Another option is a mixture of mild detergent and water, which works well for most forms of aluminum.

Borax is also a viable alternative and can be found in the laundry aisle of a supermarket. These cleaning solutions are easy to use and can remove dirt, grime, and oxidation from aluminum parts. By following the instructions and using the appropriate cleaner, you can restore the shine and cleanliness of your aluminum parts.

How Do You Clean Oxidation Off Aluminum?

To clean oxidation off aluminum, you can use a mixture of vinegar and water. Soak a cloth or sponge in the solution and scrub the oxidized areas. Rinse the aluminum thoroughly with water and dry it with a clean towel. Another alternative is to use a mild detergent mixed with water.

Apply the mixture to the oxidized areas and scrub gently with a cloth or sponge. Rinse well and dry. Borax is also an effective option. Sprinkle the borax onto a damp cloth and scrub the aluminum surface. Rinse thoroughly and dry. These methods will help remove oxidation and restore the shine to your aluminum surfaces.

Remember to always test the cleaning solution on a small, inconspicuous area before applying it to the entire surface.

How Do You Clean Aluminium Engine Casings?

To clean aluminum engine casings, follow these steps:

1. Start by rinsing the casings with water to remove any loose dirt or debris.

2. Mix a solution of mild detergent and water in a bucket.

3. Use a soft-bristle brush or sponge to gently scrub the casings with the detergent solution.

4. For stubborn stains or oxidation, you can use a mixture of vinegar and water instead of the detergent solution.

5. Rinse the casings thoroughly with clean water to remove any residue.

6. Dry the casings with a clean, lint-free cloth or allow them to air dry.

7. Optionally, you can apply a coat of aluminum polish or wax to protect the casings and restore their shine.

Remember to always wear protective gloves and eyewear when handling cleaning agents. Avoid using abrasive cleaners or tools that can damage the aluminum surface.

What Is The Best Solvent For Cleaning Aluminum?

The best solvent for cleaning aluminum is vinegar. Vinegar is an effective resource that can easily remove dirt and grime from aluminum surfaces. Another alternative is a mixture of mild detergent and water, which is a universal cleaning option for most aluminum forms. Lastly, borax, which can be found in the laundry aisle of a supermarket, is another solution to clean aluminum parts. These solvents are safe to use and do not cause damage to the aluminum surface.

Conclusion

To conclude, cleaning aluminum engine parts is a crucial maintenance step that can prolong the life and performance of your engine. By following the proper techniques and using the right products, you can effectively remove dirt, grime, and oxidation from your aluminum parts.

Remember to always wear protective gear and work in a well-ventilated area when using chemicals. Vinegar is a natural and cost-effective solution for cleaning aluminum, while mild detergent and water can be used for general cleaning purposes. If you’re dealing with heavy oxidation, borax can be a suitable option.

Additionally, there are specific aluminum cleaning products available in the market that can help achieve optimal results. Regularly cleaning your aluminum engine parts not only keeps them looking clean and shiny but also helps prevent corrosion and improve overall engine performance.

So, make it a part of your regular maintenance routine and enjoy a cleaner and healthier engine for years to come.

As an Amazon Associate, Cleanestor earns from qualifying purchases at no additional cost to you.